how to test a solenoid on a hydraulic pump

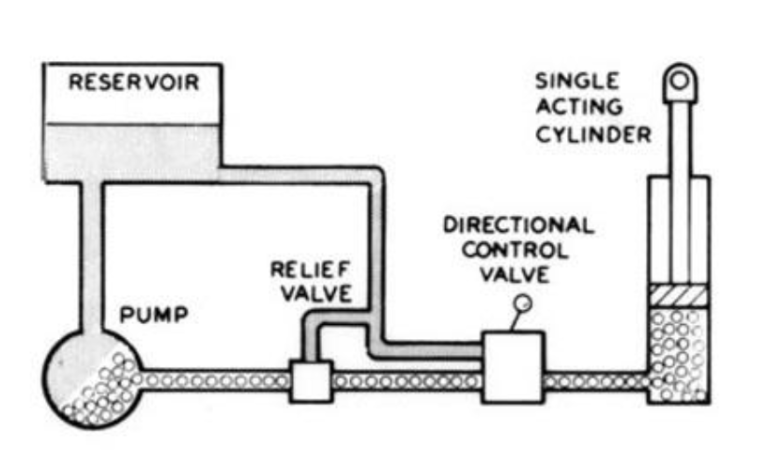

Solenoid valves are an important part of hydraulic systems. They allow the pump to flow water or oil in one direction, or to stop flowing altogether. But how do you test a solenoid valve? In this article, we’ll walk you through the steps necessary to test a solenoid on a hydraulic pump.

1. Verify that the solenoid valve is operational.

To test a solenoid valve, you first need to verify that it’s operational. To do this, you’ll need to turn on the pump and check to see if the valve opens and closes properly. If it doesn’t, there may be a problem with the solenoid valve itself.

2. Check the fluid pressure behind the solenoid valve.

Another way to test a solenoid valve is by checking the fluid pressure behind it. This can help you determine whether there’s a problem with the system or the solenoid valve. You can do this by using a pressure gauge or by measuring the amount of water or oil flowing through the valve.

3. Check for leaks around the solenoid valve.

If there are any leaks around the solenoid valve, this could cause problems with system operation. In order to test for leaks, you’ll need to temporarily close off part of the system so that you can identify where the leak is located. Then, you’ll need to repair or replace the affected part of the system.

4. Check for damage to the solenoid valve.

If there are any signs of damage to the solenoid valve, this could cause problems with system operation. In order to test for damage, you’ll need to temporarily close off part of the system so that you can inspect the valve. Then, you’ll need to repair or replace the affected part of the system.

5. Check for interference with other components of the system.

If there are any other components in the system that are interfering with the operation of the solenoid valve, this could cause problems with system operation. In order to test for interference, you’ll need to isolate the affected component(s) and determine whether they’re interfering with the valve’s function. If they are, you’ll need to repair or replace them.

6. Test the system using a water flow test rig.

If there are any problems with the system, you might also need to test it using a water flow test rig. This will help you determine the cause of the problem and whether it can be fixed.

7. Check for damage to the pump.

If there are any signs of damage to the pump, this could cause problems with system operation. In order to test for damage, you’ll need to temporarily close off part of the system so that you can inspect the pump. Then, you’ll need to repair or replace the affected part of the system.

8. Test the system using a hydraulic pressure test rig.

If there are any problems with the system, you might also need to test it using a hydraulic pressure test rig. This will help you determine the cause of the problem and whether it can be fixed.

9. Check for damage to the hydraulic system.

If there are any signs of damage to the hydraulic system, this could cause problems with system operation. In order to test for damage, you’ll need to temporarily close off part of the system so that you can inspect the system. Then, you’ll need to repair or replace the affected part of the system.

10. Return the system to normal operation.

Once you’ve checked all of the components of the system and determined that there’s no underlying problem, you can return the system to normal operation. This might involve fixing the problem or replacing one or more of the components.

What is a solenoid on a hydraulic pump?

A solenoid is a coil of metal wire that is used on hydraulic pumps to change the pressure or flow of the hydraulic fluid. By changing the pressure or flow, the pump can be made to work faster or slower, respectively. Solenoids are also used to control the direction of the fluid flow.

Solenoids are most commonly used on pumps that move liquids or slurries, as they allow the pump to be operated at a much higher pressure than traditional pumps.

Troubleshooting a failed solenoid on a hydraulic pump

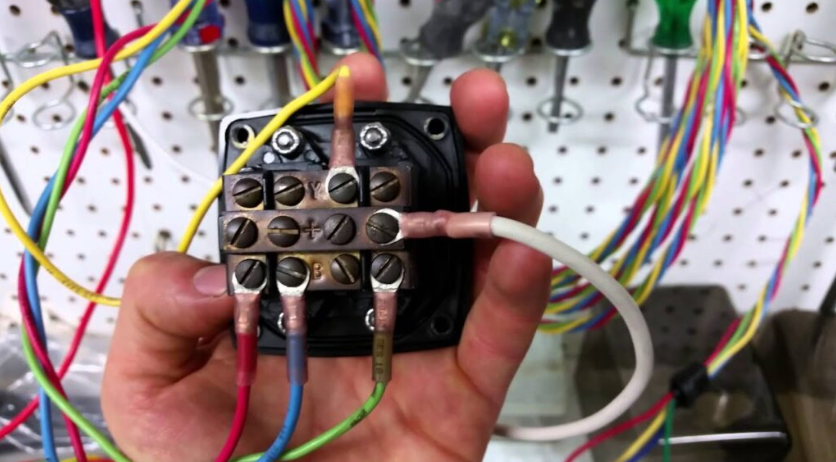

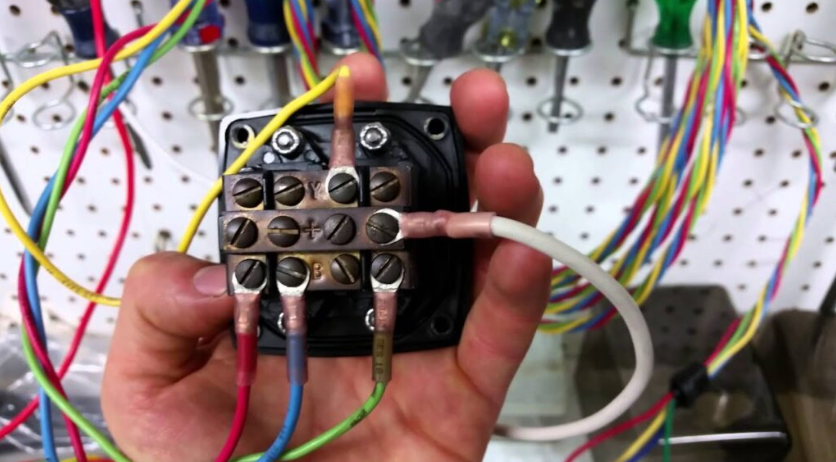

If you find that one of your hydraulic solenoids has failed, there are a few things you can do to troubleshoot the problem. First, make sure that the power to the pump is still working. Next, check the voltage at the solenoid terminals. If the voltage is low, then the solenoid may be defective and needs to be replaced. Finally, try rotating the shaft of the pump in different directions to see if the problem lies with the solenoid itself or with a connecting rod or sealant. If all of these tests fail to identify the cause of the failure, then it may be necessary to replace the entire hydraulic pump assembly.

What to do if you test a solenoid and it’s not working correctly?

If you suddenly notice that your hydraulic pump is not working as it should, there’s a good chance that your solenoid has failed. In this article, we’ll show you how to test a solenoid on a hydraulic pump to determine whether it’s the source of the problem.

If your solenoid is not the source of the problem, you may still have a problem with your hydraulic pump. In this case, you’ll need to replace the pump.

1. Disconnect the power to the pump.

2. Remove the cover plate on the solenoid.

3. Inspect the solenoid for damage or debris. If you find anything, remove it before proceeding.

4. Test the solenoid by plugging it into an outlet and turning on the power to the pump. If the solenoid works, there’s no need to continue with step 5. If the solenoid does not work, test it further by replacing the component.

5. Reinstall the cover plate and test the pump again.

If the solenoid is the source of the problem, you’ll need to replace it.

How to test a solenoid on a hydraulic pump

Testing a solenoid on a hydraulic pump can be done in a few different ways. One way is to use an ohmmeter to measure the resistance between the power supply and the solenoid. If the resistance is low, then the solenoid may be defective and need to be replaced. Another way to test a solenoid is to use a voltmeter to measure the voltage at the solenoid terminals. If the voltage is below normal operating levels, then the solenoid may be defective and need to be replaced.

Afsluiting

If you’re looking to troubleshoot a solenoid on a hydraulic pump, there are several things you’ll need to do in order to determine the problem. You’ll need to take measurements of the solenoid, compare them against specifications, and test for continuity between the components. By following these steps, you should be able to quickly identify and correct any issues with your solenoid.