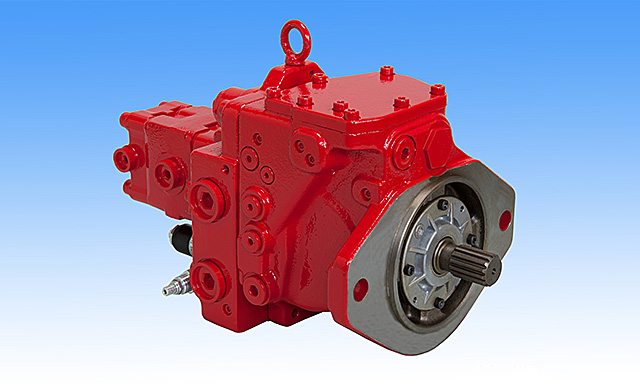

MPV & Pompe idrauliche BPV da Linde

Linde is a leading manufacturer of hydraulic pumps for the automotive industry. The company offers a complete range of products including aluminium and magnesium alloy pistons, high-pressure valves, piston rings, and seals.

The MPV series of hydraulic pumps are designed for use in multiple applications such as passenger cars, trucks and buses. These pumps feature a compact design that allows them to be installed in tight spaces while offering high flow rates.

The BPV series consists of high-pressure valves that can be used as diverter valves or dump valves on hydraulic systems in vehicles such as cars, trucks and buses. They are designed to achieve pressure control within the system by reducing or increasing the flow rate.

U Linde BPV Hydraulic Pump/Linde MPV Hydraulic Pump is the only choice for heavy-duty applications.

MPV Series (Medium Pressure Vacuum)

The MPV series of pumps are designed for a wide range of uses. They can be used in both low and high pressure applications, with flow rates ranging from 10 to 100 liters per minute (1/4 to 2 gallons per minute). The MPV is available in single-stage or two-stage configurations, as well as a variety of different pressure ratings.

BPV Series (High Pressure Vacuum)

The BPV series of pumps are designed for high-pressure applications where vacuum levels must be maintained at their lowest possible levels. These pumps can handle pressures up to 30 bar (450 psi). The BPV is available in single-stage or two-stage configurations, as well as a variety of different pressure ratings.

The MPV/BPV pumps feature a compact design and high pressures, up to 50 bar, making them ideal for closed circuits with large flows.

The MPV/BPV pumps feature a compact design and high pressures, up to 50 bar, making them ideal for closed circuits with large flows. In addition, the pumps are equipped with an integrated pressure relief valve, which prevents overpressure in the system.

The MPV/BPV pumps from Linde (formerly Emitec) are compact and highly efficient. They are suitable for pumping oil-based hydraulic fluids where large volumes have to be moved at high pressures. The MPV pump can handle oil-based fluids up to 400°C (752°F), while the BPV model is designed for use with water-based hydraulic fluids up to 300°C (572°F).

The nominal pressure of the pump can be switched steplessly between 10 and 50 bar. For higher system pressures, the nominal pressure can be increased by a factor of 1.2 or 1.5 via an optional drive gear and pump housing.

The nominal pressure of the pump can be switched steplessly between 10 and 50 bar. For higher system pressures, the nominal pressure can be increased by a factor of 1.2 or 1.5 via an optional drive gear and pump housing.

The MPV series is available with a variety of different motors for high-performance applications (see table below). The pumps are designed for use in hydraulic systems with high demands on flow capacity and pressure tolerance. They are used in mobile hydraulics, such as construction machinery, agricultural equipment and mining vehicles.

The BPV series is available with a variety of different motors for high-performance applications (see table below). It is ideal for use in large stationary systems such as cranes and overhead crane systems, railcar bogies and crane carriers.

A hydraulic fan provides continuous cooling of the hydraulic fluid, ensuring constant output and reliability. This fan can be turned off automatically when necessary (via a temperature switch).

A hydraulic fan provides continuous cooling of the hydraulic fluid, ensuring constant output and reliability. This fan can be turned off automatically when necessary (via a temperature switch).

MPV & BPV pumps are pressure-operated pumps – they only operate under pressure. They have no built-in pressure relief valve and are therefore less sensitive to overpressure than other types of pumps. The pump is driven by the turbine wheel at the same speed as that of the engine’s crankshaft. The pump’s internal parts move up and down relative to one another under pressure, so there is no need for bearings or seals in the pump housing.

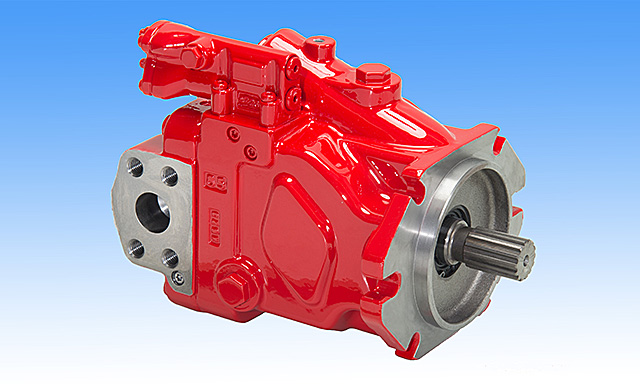

With a flange mounting on the engine, the MPV/BPV Series pumps provide easy installation and maintenance access.

With a flange mounting on the engine, the MPV/BPV Series pumps provide easy installation and maintenance access. The pumps are available with a wide range of pressure ratings and flow capacities up to 28,000 psi (200 bar). The series offers stainless steel or carbon steel construction with ball/roller or vane type pistons as well as double diaphragm designs. For ease of serviceability, the pump can be removed without draining the oil supply line

The MPV/BPV Series is ideal for use in industrial applications such as oilfield drilling rigs, offshore platforms, and marine applications where high pressure is required at low flow rates.

Modular construction allows for interchangeability between the MPV and BPV series pump components.

The Linde MPV and BPV hydraulic pumps are designed for use in industrial applications where hydraulic fluid must be conveyed at pressures up to 3,000 psi (206 bar). The modular construction of these pumps allows for interchangeability between the MPV and BPV series pump components.

The Linde MPV Series is available with a variety of port configurations including straight, 90°, 45° and 90° elbows. Pumps are available with two-way or three-way directional control valves and can be supplied with integral pressure relief valves. Two versions are available: fixed displacement or variable displacement. Options include pressure gauges, filters and check valves.

The Linde BPV Hydraulic Pump/Linde MPV Hydraulic Pump are seamless power survivors in any environment.

Linde’s MPV and BPV hydraulic pumps are designed to increase productivity and reduce maintenance costs by combining high pressure with high efficiency. The MPV/BPV pumps are used in a wide range of applications, including mining, construction, oil & gas and marine industries.

The MPV/BPV pumps are available in a wide range of sizes and configurations, with high-pressure capabilities up to 10,000 psi (70 bar). Each model is designed for maximum durability and long service life in harsh operating conditions. The pumps feature an integrated pressure relief valve that helps prevent overloading from resulting in catastrophic failure. They also include an integral gearbox for reduced weight and space consumption.

Linde has been an innovator in the hydraulic fields for years, and certainly shows no signs of stopping. And with advanced technologies like the BPV for oil refining and petrochemical industries, it is easy to see why Linde is a worldwide leader in fluid handling solutions.