How long do hydraulic motors last?

Hydraulic motors are one of the most popular types of motors because they’re efficient and powerful. With proper maintenance, hydraulic motors can last for many years. However, there are a few things to keep in mind if you plan on using a hydraulic motor for a long period of time.

First, make sure that the motor is properly lubricated. Over time, oil can thicken and cause the motor to run less efficiently.

Second, be sure to check the impeller for wear and tear. If it’s damaged or worn out, this can reduce the motor’s efficiency.

Finally, keep an eye on the seals around the motor casing. If they’re damaged or leaky, this can also cause the motor to lose efficiency.

What is a hydraulic motor?

A hydraulic motor is a type of electric motor that uses pressurized fluid to move objects. They’re usually found in industrial and construction applications, where their high torque and power can be beneficial.

How long do hydraulic motors last?

Generally speaking, hydraulic motors last longer than electric motors. This is because they’re less likely to fail due to wear and tear, or due to electrical issues. Additionally, they’re typically built with a longer lifespan in mind. That said, there are always exceptions – so it’s important to monitor the motor’s performance regularly.

How do hydraulic motors work?

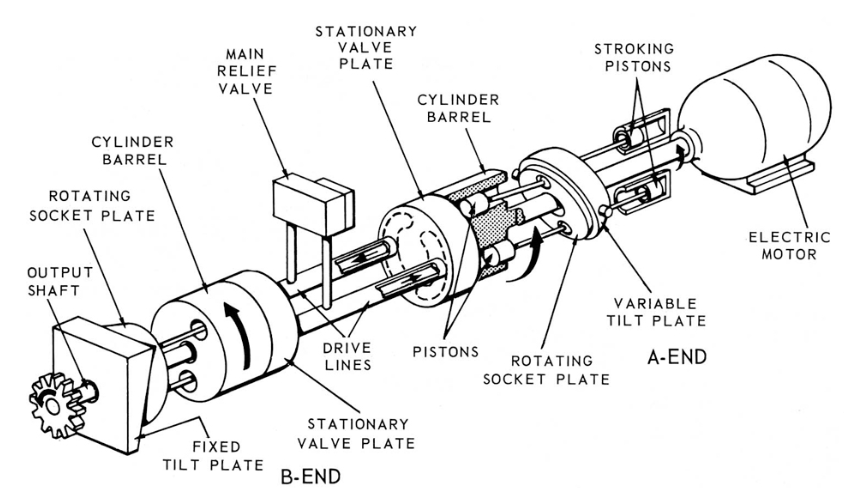

Hydraulic motors are one of the most common types of motors used in industrial and construction applications. They use pressurized fluid to rotate a shaft. The lifespan of a hydraulic motor depends on a variety of factors, including the type of fluid used, the maintenance and repair procedures used, and the type of load the motor is subjected to.

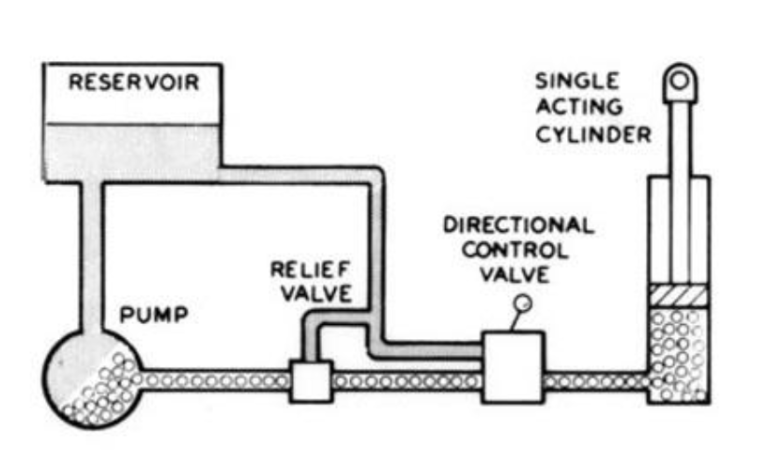

Hydraulic motors work by using a fluid to transmit power from the motor to the shaft. The fluid is pressurized, and this pressure is used to rotate the shaft. The pressure in the system can be controlled using valves, which allows for varying levels of power to be transmitted to the shaft.

Hydraulic motors are typically used in applications where torque is required. This means that they are often used in combination with other tools and equipment, such as cranes and hoists. They are also commonly found in industrial settings, such as factories and mines.

What are the benefits of using hydraulic motors?

Hydraulic motors offer a number of benefits over traditional electric motors, including longer lifespan and reduced noise. They are also easier to maintain and can be used in a wider range of applications than electric motors.

What are the drawbacks of using hydraulic motors?

There are a few drawbacks to using hydraulic motors. First, they can be more expensive than electric motors. Second, they require more maintenance than electric motors, including regular lubrication and inspection. Finally, they can be less efficient than electric motors in some applications.

What can you do to prolong the life of a hydraulic motor?

There are a few things you can do to prolong the life of your hydraulic motor. Here are five tips:

1. Make sure the motor is kept clean and free of debris. This will help reduce friction and wear on the moving parts.

2. Regularly check the seals around the motor housing for signs of wear or leakage. If there is any leakage, replace the seals as soon as possible to keep the motor running smoothly and prevent damage.

3. Replace worn or damaged parts as soon as possible to prevent them from causing further damage and extending the life of the motor.

4. Inspect all hoses and connections for leaks and damage, and replace them as needed. This will help reduce friction and wear on the motor assembly.

5. Make sure you have a maintenance plan in place to keep your hydraulic system running smoothly and efficiently. This will help ensure that your motor lasts longer overall.

What Are the Limitations of Hydraulic Motors?

The lifespan of a hydraulic motor depends greatly on the type of hydraulic motor being used and how it is maintained. Motors that are used for leisure or commercial purposes typically have a longer lifespan than those used in industrial settings. However, there are some general limitations to keep in mind when it comes to hydraulic motors.

One limitation is that hydraulic motors cannot operate under high temperatures or pressures. This is because the increased temperature or pressure can cause the seals to breakdown and lead to engine failure. In addition, hydraulic motors are also limited by their oil supply. If the oil supply becomes depleted, the motor will stop working.

How do hydraulic motors wear out?

Hydraulic motors can last anywhere from 10,000 to 100,000 hours depending on the type of motor and how it is used. The lifespan of a hydraulic motor depends on a variety of factors, including the type of fluid used, the quality of the seals and fittings, and the maintenance procedures followed.

Over time, the fluid inside the motor will start to seep out and cause the motor to wear down. Additionally, the seals and fittings can become corroded, which will also affect the motor’s performance. Finally, improper maintenance procedures can also lead to wear and tear on the motor.

How long do hydraulic motors last?

Hydraulic motors are a common type of motor found in many different devices. They tend to last longer than other types of motors, but there are some things that can affect their lifespan.

Overall, hydraulic motors last longer than electric motors and are typically easier to maintain. Regular inspection and replacement of parts is essential to keeping them running smoothly and preventing damage.

Kammalawa

Hydraulic motors are a very efficient way to power various machines and equipment, but like with any type of machinery, they will eventually wear out. The length of time that a hydraulic motor lasts varies depending on the make and model, but in general, expect them to last around 10,000 hours or more. At this point, it is important to have your hydraulic motor inspected by a professional so that any necessary repairs or replacements can be made.

How long do hydraulic motors last?please clicktopkitparts karin gani