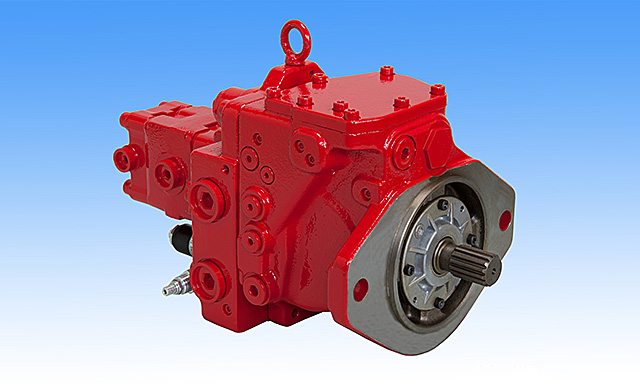

A brief overview of the Linde PV Hydraulic Pump used in the chemical industry.

The Linde PV Hydraulic Pump is a positive displacement pump designed for use in the chemical industry. The pump is suitable for both low and high viscosity fluids and can be used in applications such as slurry handling, polymerization, water treatment and more.

The Linde PV Hydraulic Pump uses a positive displacement screw to move liquid through the rotating central shaft. This action creates a constant flow rate which can be adjusted by changing the speed at which the screw spins.

Linde PV Hydraulic Pumps are constructed using a variety of materials including stainless steel, bronze and aluminum. These materials ensure that the pumps are durable enough to withstand harsh chemical environments without corroding or otherwise failing prematurely.

De Linde PV Hydraulic pump is a piston pump that is designed to be used in the chemical process industry.

The Linde PV Hydraulic pump is a piston pump that is designed to be used in the chemical process industry. It will deliver a flow rate of up to 20 m³/h and a pressure of up to 10 bar. The pumps can operate at temperatures from -20°C to +85°C and are available in sizes ranging from 2″ to 24″.

The Linde PV series piston pumps have been designed with an eye on safety. All models come with our patented safety valve technology that halts the movement of the pistons if there is any obstruction in the system. The pistons are also equipped with an anti-vibration system, which minimises the energy consumption and operating noise levels.

This type of industrial pump has a simple round-trip flow rate and it does not need any additional equipment for its operation.

This type of industrial pump has a simple round-trip flow rate and it does not need any additional equipment for its operation. It is a pneumatic pump with positive displacement, which means that the volume of fluid pumped is directly proportional to the pressure exerted over the piston. The Linde PV Hydraulic Pump is designed to transfer liquids with high viscosity or abrasive particles such as mining materials or slurries.

The Linde PV Hydraulic Pump has a great advantage over other types of pumps because it can handle high temperatures, but only up to 200 degrees Celsius (392 degrees Fahrenheit). This makes it ideal for use in hot environments like power plants where there are large amounts of steam available for heating your equipment.

Most commonly, this kind of industrial pump is used in petrochemical plants and other types of industrial plants.

The Linde PV Hydraulic Pump is a double-acting piston pump that relies on the pressure differential between its two chambers to raise liquid from one level to another. The Linde PV Hydraulic Pump can be used for many purposes, including pumping liquids in chemical laboratories and other industrial applications.

The Linde PV Hydraulic Pump has a single cylinder with two pistons connected by a common rod. One piston is attached to the crank shaft, while the other remains stationary. As the crank shaft turns, it drives both pistons up and down in their respective cylinders. The amount of fluid displaced is proportional to the distance traveled by each piston — if one cylinder discharges more than the other, then the output flow rate will be higher than if they were both equal sized cylinders.

The Linde PV Hydraulic pump works by rotating the fluid from an outlet to an inlet, through the use of two hydraulic pumps.

The Linde PV Hydraulic Pump is a high-pressure, high-volume pump that can be used for a wide range of applications. The pump is powered by electricity and can deliver up to 30 bar (400 psi) at 10 liters per minute. This makes it suitable for use in both stationary and mobile systems such as firefighting equipment, construction equipment and industrial vehicles.

The two pistons in the Linde PV Hydraulic Pump are connected via a piston rod to a crankshaft. When the pistons move, the crankshaft rotates 90 degrees and turns the gears attached to them so they can turn another gear which is attached to an output shaft that turns another gear attached to an input shaft so it can create movement on one side while creating pressure on other side.

The two hydraulic pumps are mounted on one another, with one at the leading edge and one at the trailing edge.

In order to ensure the highest possible quality and reliability, the Linde PV Hydraulic Pump is designed in accordance with ISO 9001 and ASME codes. The two hydraulic pumps are mounted on one another, with one at the leading edge and one at the trailing edge.

The flow rate of the pump is based on an average solar radiation value of 1,800 kWh/m2 per year. The pump has a lifetime of more than 10 years if operated in a grid-connected system. For off-grid applications, we recommend using a second pump as backup in case of failure of the main unit.

Its rotation rate is six degrees per revolution of the fluid flow, which makes it relatively fast for a set of hydraulic pumps.

The Linde PV Hydraulic Pump is a single-stage centrifugal pump that is used in applications such as mining, oil and gas, construction and agriculture. Its body is made of cast iron, making it extremely durable and long-lasting. This pump has two ports: one for the suction port and one for the discharge port. It also comes with an option to make it self-priming to ensure easy installation without any difficulty.

A single revolution takes between 15 and 20 seconds, depending on the application.

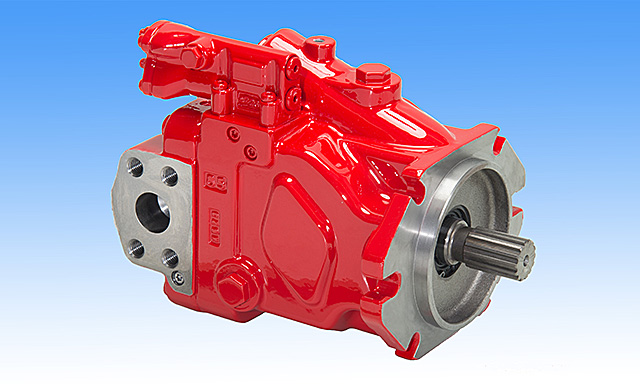

Linde Engineered Products has developed a hydraulic pump that is able to generate high pressure with very low volume flow rates. The solution uses a standard camshaft drive with an integrated hydraulic pump and a separate fluid reservoir. The pump’s special design enables it to produce high pressures without increasing the volume flow rate significantly – making it suitable for use in applications where space is limited.

The new Linde PV Hydraulic Pump is designed for use with Linde’s own range of compressed air generators. It can also be used with other brands of compressed air generator when used in combination with an adapter kit from Linde.

De Linde PV Pump works by rotating the fluid from an outlet to an inlet, while reducing friction between the rotating sections using internal gears.

The pump is designed to work over a wide range of pressures and flow rates by altering the gear ratio. The main components are a gearbox, casing and motor.

The gearbox has two input shafts that connect directly to the hydraulic system. One shaft connects to the hydraulic pump via a hydraulic hose or pipe, while the second connects to the hydraulic motor via another hydraulic hose or pipe. The gearbox also has two output shafts that connect directly to the hydraulic actuator. One shaft connects to the hydraulic motor via another hydraulic hose or pipe, while the other connects directly into the actuator via yet another hydraulic hose or pipe.

The Linde pump has a long and proud history of contributing to the development of the PV market worldwide, thanks to its reliability and efficiency. Its place in the market is continually being reinforced by continuing developments in product technology and range. The Linde PV Hydraulics segment is also proud to be involved with many innovative partners, working together towards the future of solar power generation.