Hur ökar jag trycket på min hydraulpump?

hydraulic pump is an important piece of equipment in any industrial setting, and it needs to be in good working order for your business to run smoothly. However, sometimes the pressure on the pump can become too high, causing it to break down or wear out prematurely. In this article, we’ll show you how to increase the pressure on your hydraulic pump so that it works as efficiently as possible.

Vad är en hydraulpump?

A hydraulic pump is a device that uses the pressure of a fluid to move or perform work. This is done by using a piston and cylinder to create a flow of pressurized fluid.

Pumps are used in a variety of applications, including water pumps, oil pumps, and gas pumps. They are also used in industrial processes, such as mining and manufacturing.

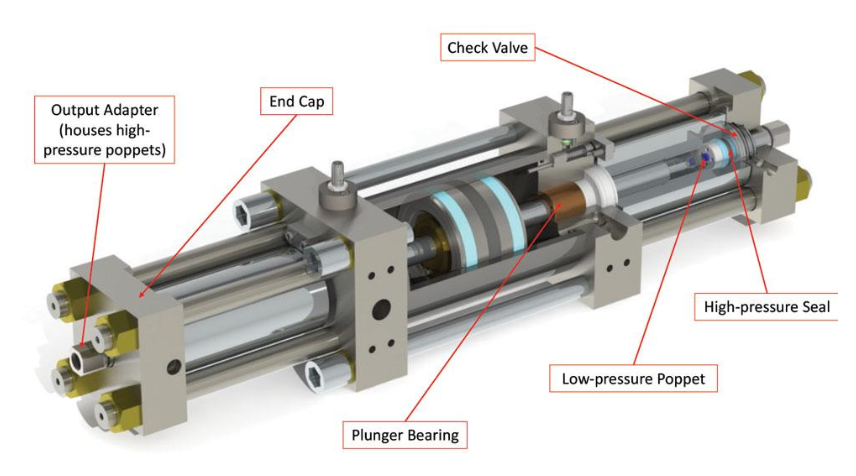

A hydraulic pump is made up of different parts, including the motor, the gearbox, the cylinder, and the piston. The motor converts energy from an engine into rotational motion that can be used to power the pump. The gearbox contains the gears that allow the piston to move up and down. The cylinder holds the pressurized fluid and has a valve that allows it to flow into and out of the pump. The piston is located at the bottom of the cylinder and moves up and down as the gearbox rotates it. This movement forces the pressurized fluid through the valve and out of the cylinder.

There are many different types of hydraulic pumps available on the market today. Some common types include positive displacement pumps, centrifugal pumps, and vane pumps. Each type has its own advantages and disadvantages, so it is important to

Hur fungerar en hydraulpump?

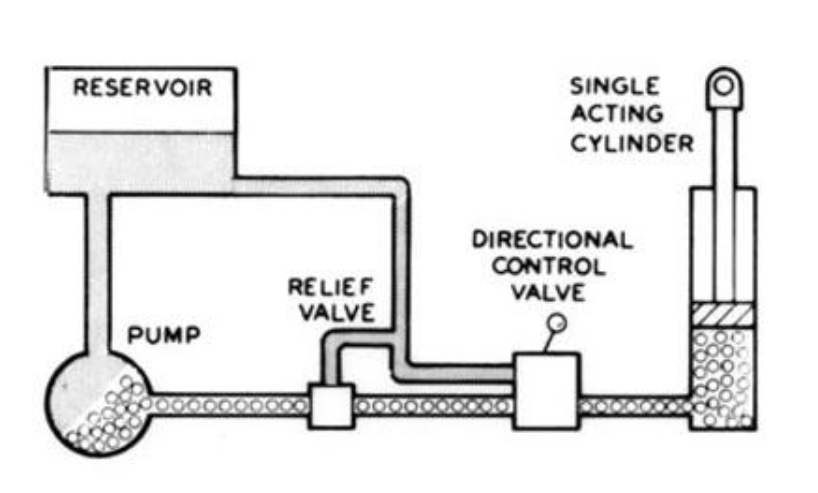

Hydraulic pumps are one of the most common types of engine power plants. A hydraulic pump is a mechanical device that uses pressure to move fluid. The fluid can be anything from oil to water. In a hydraulic pump, the fluid is pressurized by the engine and sent through a system called the cylinder. The cylinder contains a series of pistons that move up and down. This movement causes the fluid to move from one side of the cylinder to the other.

The hydraulic pump works because of the pressure that the engine creates. This pressure is used to push the fluid through the system. The pump can move a lot of fluid, which is why it is so important in engines.

There are a few different types of hydraulic pumps. The most common is the piston pump. This type of pump uses pistons to move the fluid. Other types of pumps use hydraulic cylinders, which use pressurized fluid to move the pistons.

Why do I need to increase the pressure on my pump?

When you are using your hydraulic pump, the pressure is essential to getting the job done. The higher the pressure, the more force the pump can exert. If the pressure is not high enough, the pump may not be able to push fluid through the lines quickly enough and it could cause damage. There are a few ways to increase the pressure on your pump:

– Make sure all connections are secure and tight. Loose connections can cause low pressure.

– Check for air bubbles in the system. Air bubbles will reduce pressure and can create problems down the line.

– Increase the size of your pump suction pipe. A larger pipe will allow more fluid to flow through the pump faster, increasing pressure.

How do I determine pressure on a hydraulic pump?

There are a few ways to measure the pressure on a hydraulic pump. One way is to use a gauge. Another way is to use a pressure sensor. The most common pressure sensor is the mercury manometer.

How can I prevent a hydraulic pump from overpressuring?

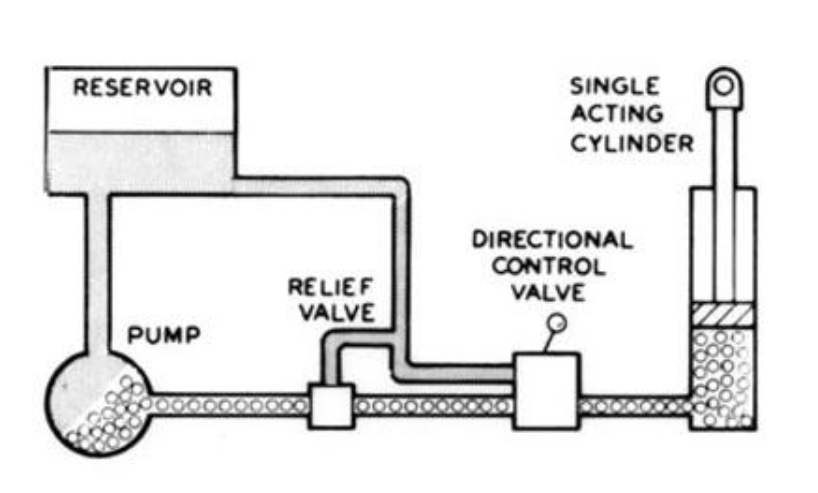

There are a few ways to prevent a hydraulic pump from overpressuring. One way is to use a pressure controller. Another way is to use a relief valve.

How to increase the pressure on your hydraulic pump

If you are experiencing low pressure on your hydraulic pump, there are a few things you can do to increase the pressure. One option is to replace the pump orifice. Another option is to increase the pressure source.

If you are experiencing low pressure on your hydraulic pump, one option is to replace the pump orifice. This can be done by removing the pump cover and replacing the orifice with a larger one. This will increase the pressure and help resolve the issue.

Another option is to increase the pressure source. This can be done by adding more hydraulic fluid to the system or by increasing the hydraulic pressure. Increasing the hydraulic pressure can be done by using a higher-pressure pump or by increasing the hydraulic rating of your system.

Why does pressure matter on a hydraulic pump?

Pressure is a critical factor in the function of a hydraulic pump. The higher the pressure, the more efficiently the pump can transfer energy to move fluid. This is why it’s important to maintain pressure on a hydraulic pump when it’s in use. There are a few ways to increase the pressure on a hydraulic pump.

One way to increase pressure is to add more cylinders to the system. This will create a greater internal pressure and allow the pump to work at its full potential. Another way to increase pressure is to use an air compressor to push air into the system. This will augment the power of the engine and help to raise pressure on the system. Finally, you can also use valves and manifolds to adjust pressure in specific areas of the system. By adjusting pressure, you can ensure that all parts of the pump are working at their best potential.

Advice for increasing the pressure on my hydraulic pump

If your hydraulic pump is not providing the pressure you need to operate your equipment, there are a few things you can do to increase the pressure.

The first thing to check is the pressure relief valve on your pump. This valve allows excess pressure to escape from the pump if it becomes overworked. If the valve is not opening as it should, you may need to replace it.

Another option is to upgrade your pump. Higher-pressure pumps are available that can provide more leverage and flow capacity, allowing you to operate your equipment at higher pressures without damaging it.

If these measures don’t solve the problem, you may need to consider replacing your pump altogether.

Slutsats

If you are experiencing low pressure on one of your hydraulic pumps, it is likely that the pump has become clogged. This can be caused by a variety of things, but the most common culprits are bits of debris or fiber from the surrounding environment getting caught up in the pump’s impeller and preventing it from performing at its best. If you find that your pump is struggling to produce enough pressure even with cleanings and inspections performed regularly, it might be time to replace the pump altogether.

How do I increase the pressure on my hydraulic pump. please clicktopkitparts se mer