Hydraulic gear pumps are used to convert mechanical energy into hydraulic energy in machinery and equipment. They are commonly used in industrial and mobile hydraulics for power steering, lifting, and material handling. These pumps deliver a steady flow of hydraulic fluid to actuate cylinders, motors, and other hydraulic components, making them ideal for high-pressure systems in construction, agriculture, and manufacturing.

Have you ever wondered what hydraulic gear pumps are used for? Are you curious about how they contribute to various industrial and mobile applications? Understanding hydraulic gear pump applications can be challenging due to the wide variety of machinery and industries they serve. From powering heavy construction equipment to providing precise motion control, these pumps are vital in many sectors. In this article, we’ll explore the different uses of hydraulic gear pumps, how they work, and why they are essential for high-pressure systems. Let’s dive in and answer the question: What are hydraulic gear pumps used for?

1. Industrial Machinery

Hydraulic gear pumps are crucial in powering various types of industrial machinery. They provide the essential hydraulic energy needed to operate systems such as presses, injection molding machines, and automated conveyor systems. In stamping and injection molding, for instance, precise and consistent motion control is required for producing high-quality parts, and hydraulic gear pumps are perfectly suited to deliver such performance. The steady, reliable power generated by these pumps helps maintain consistency in production lines, reducing downtime and improving efficiency. Industrial operations like forging, pressing, and bending involve substantial forces, and the robust design of hydraulic gear pumps ensures that these forces are effectively generated and maintained. The versatility and durability of hydraulic gear pumps make them indispensable in the manufacturing sector, where efficiency, precision, and reliability are paramount for day-to-day operations.

2. Construction Equipment

In the construction industry, hydraulic gear pumps are indispensable for operating heavy machinery like excavators, loaders, bulldozers, and cranes. These machines rely heavily on hydraulic power to perform tasks like digging, lifting, pushing, and moving heavy materials across construction sites. For example, an excavator uses its hydraulic system to maneuver the boom, stick, and bucket, enabling it to dig and lift soil or debris with precision and strength. The reliability of hydraulic gear pumps is critical in these operations because even a small malfunction can lead to significant project delays and increased operational costs. The durability of these pumps, along with their ability to provide constant flow under high pressure, ensures that construction machinery can perform demanding tasks efficiently and with minimal downtime. Without hydraulic gear pumps, the construction industry would face significant challenges in achieving the efficiency and productivity required for modern infrastructure projects.

3. Agricultural Machinery

Hydraulic gear pumps play an essential role in powering agricultural equipment, such as tractors, combines, harvesters, and sprayers. These machines require hydraulic power to operate various attachments and implements, including plows, seed drills, and harvesting heads. For instance, in a combine harvester, hydraulic gear pumps are used to control the header, the reel, and the unloading auger, ensuring that each component operates smoothly and efficiently. The ability to provide consistent hydraulic flow is crucial in agricultural settings, where seasonal workloads demand reliability and high performance. Farmers depend on hydraulic power to manage tasks such as soil preparation, planting, irrigation, and harvesting, all of which contribute to overall farm productivity. By delivering a steady flow of hydraulic fluid, gear pumps allow agricultural machinery to perform a wide range of tasks with precision, reducing labor costs and increasing yields, which is especially important in today’s competitive agricultural industry.

4. Automotive Systems

In the automotive sector, hydraulic gear pumps are integral to several key systems, including power steering, automatic transmissions, and hydraulic braking. Power steering systems rely on hydraulic pumps to make steering effortless for the driver, allowing for smoother and more responsive control. The hydraulic gear pump supplies pressurized fluid to assist in turning the wheels, significantly reducing the amount of physical effort required, especially when maneuvering at low speeds or when the vehicle is stationary. In automatic transmission systems, hydraulic gear pumps help facilitate smooth gear shifts by maintaining consistent hydraulic pressure. The same principle applies to hydraulic braking systems, where pressurized hydraulic fluid is used to amplify the braking force applied by the driver, ensuring effective and responsive braking. Without the reliability of hydraulic gear pumps, modern vehicles would lack the safety and comfort features that drivers have come to expect, making them an essential component in automotive design.

5. Chemical Processing

The chemical industry often involves handling and transferring fluids with unique properties, including high viscosity, corrosiveness, or toxicity. Hydraulic gear pumps are well-suited for these applications because of their ability to provide precise flow control and handle a wide range of fluid types. These pumps are used to move chemicals such as acids, solvents, and polymers between containers or through processing equipment. Their robust construction materials, often including corrosion-resistant alloys, ensure that the pumps can withstand the harsh environments typical of chemical plants. For example, in the production of polymers, a hydraulic gear pump may be used to move viscous liquids through various stages of the process while maintaining a consistent flow rate. The precise control offered by hydraulic gear pumps is crucial for maintaining product quality and ensuring that processes run efficiently, especially in operations that require exact chemical dosing or mixing.

6. Food and Beverage Industry

Hydraulic gear pumps also find applications in the food and beverage industry, where sanitary and precise fluid handling is essential. These pumps are used for transporting food-grade liquids, such as oils, syrups, dairy products, and other viscous substances, throughout the production process. For example, in a dairy processing plant, hydraulic gear pumps help in moving milk and cream through pasteurization, homogenization, and filling stages. The materials used in these pumps are often selected to meet food safety standards, ensuring that there is no contamination of the food products. Additionally, the ability of hydraulic gear pumps to maintain a consistent flow rate is particularly valuable in food production, where precise amounts of ingredients must be added to maintain product consistency and quality. The hygiene, precision, and durability of hydraulic gear pumps make them well-suited to the stringent requirements of the food and beverage industry, contributing to the overall safety and quality of consumable products.

Slutsats

Hydraulic gear pumps are versatile and vital components across numerous industries, from powering construction machinery to facilitating chemical processing and food production. Their ability to provide consistent hydraulic power makes them indispensable for a wide range of applications. Whether you’re in manufacturing, agriculture, or automotive, understanding hydraulic gear pump applications helps optimize their use effectively. If you have any questions or want to share your experiences with hydraulic gear pumps, feel free to leave a comment below. We’d love to hear from you!

FAQ

1. What is a hydraulic gear pump used for?

Hydraulic gear pumps are used to convert mechanical energy into hydraulic energy, powering machinery and equipment. They are commonly found in applications such as industrial machinery, construction equipment, agricultural machines, and automotive systems where they provide consistent hydraulic power for various operations.

2. How does a hydraulic gear pump work?

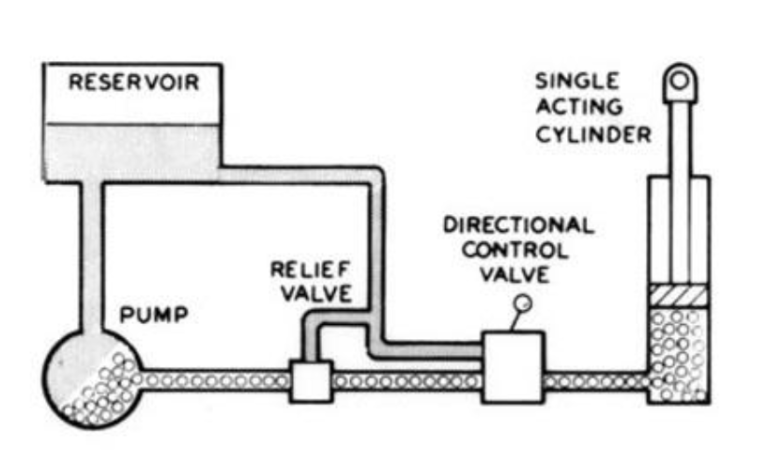

A hydraulic gear pump works by using two interlocking gears to create a flow of hydraulic fluid. As the gears rotate, they create a vacuum at the pump inlet, drawing in fluid. The fluid is then carried between the gear teeth to the outlet, where it is pressurized and directed into the hydraulic system.

3. What are the advantages of hydraulic gear pumps?

Hydraulic gear pumps are known for their durability, reliability, and ability to handle high-pressure applications. They are compact, easy to maintain, and offer a consistent flow rate, making them ideal for both mobile and industrial applications that require dependable hydraulic power.

4. Where are hydraulic gear pumps commonly used?

Hydraulic gear pumps are used in a variety of sectors, including construction, agriculture, automotive, and chemical industries. They are found in equipment such as excavators, tractors, power steering systems, and processing machinery, providing hydraulic power for lifting, moving, and fluid handling tasks.

5. How do you maintain a hydraulic gear pump?

Maintaining a hydraulic gear pump involves regular inspections for wear and tear, checking fluid levels, and ensuring there are no leaks. Proper filtration of the hydraulic fluid is essential to prevent contaminants from damaging the pump. Routine maintenance helps extend the life of the pump and maintain its efficiency.