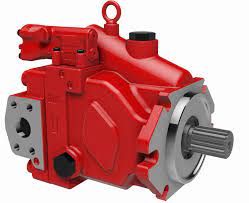

Kawasaki K3VL Hydraulpump Granskning

The Kawasaki K3VL is a powerful hydraulic pump that provides fluid at up to 3000 PSI. This makes it ideal for almost any job you can throw at it, including those requiring high pressure levels. It’s also easy to use thanks to its easy-to-access control panel and large reservoir tank. This means you don’t have to refill the tank every time you use it – just turn off the machine, wait for all pressure to drop out and then remove the hose from your machine. You won’t even have to stop what you’re doing!

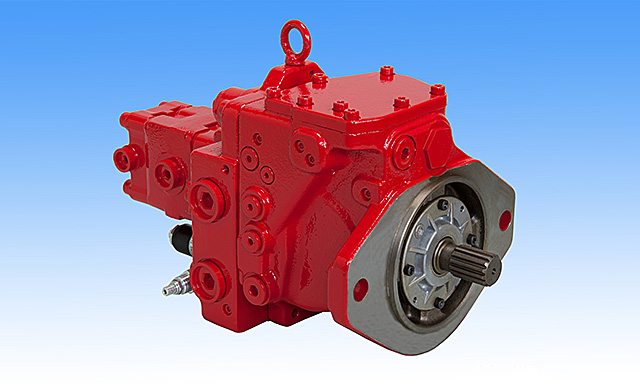

Kawasaki K3VL Hydraulic Pump is a complete unit and consists of a Kawasaki K3V112DT variable volume pump and an integrated air valve.

The Kawasaki K3VL Hydraulic Pump consists of a Kawasaki K3V112DT variable volume pump and an integrated air valve. The Kawasaki K3VL Hydraulic Pump is designed to provide high pressure hydraulic fluid at low flow rates. It is ideal for use as an auxiliary power source in mobile equipment.

The Kawasaki K3VL Hydraulic Pump features a compact design that allows easy installation and maintenance. The unit can be mounted directly on the engine or connected to an external source of hydraulic fluid via a mounting bracket.

Kawasaki K3VL Hydraulic Pump is rated at up to 250 psi, with flow rates from 0.5 GPM up to 1 GPM at 150 psi, depending on model. The pump assembly meets ISO 8846-1:2009 standards for diesel engines, making it suitable for use in most industrial applications.

The K3VL hydraulic pump is driven by an electric motor or an internal combustion engine through a drive shaft and the transmission gearbox.

The Kawasaki K3VL hydraulic pump is driven by an electric motor or an internal combustion engine through a drive shaft and the transmission gearbox. The pump itself has three cylinders, each one with its own piston and cylinder head. The pistons are connected to each other through a connecting rod. A crankshaft rotates around its axis inside the second cylinder head to drive all three pistons at once.

The first cylinder head contains a camshaft that controls the opening of the valves in each cylinder head. When the valve opens up, it lets oil flow out of that cylinder into the next one, where it gets compressed until it passes through another valve which then closes up again. This cycle continues until all three cylinders have emptied themselves completely and need another fill-up cycle to start over again.

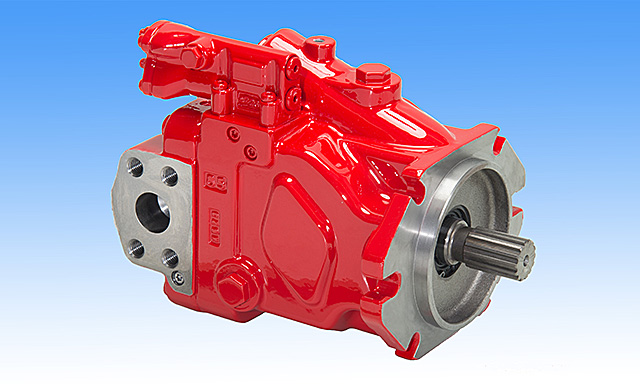

The variable displacement of the Kawasaki K3VL hydraulic pump allows the input speed of the hydraulic pump to remain constant while maintaining pressure or while changing the direction of rotation.

The variable displacement of the Kawasaki K3VL hydraulic pump allows the input speed of the hydraulic pump to remain constant while maintaining pressure or while changing the direction of rotation. The Kawasaki K3VL series includes a wide range of pumps with capacities ranging from 80 to 500 GPM (380 to 2000 LPM).

The Kawasaki K3VL pump has a compact design and is available in horizontal, vertical and high-vacuum models with discharge pressures up to 6000 PSI (420 bar). The variable displacement ratio allows for easy operation in either direction, which makes it ideal for applications requiring variable flow rates.

In applications where multiple hydraulic pumps are used, Kawasaki K3VL hydraulic pumps are ideal as motors can be connected in parallel and shared power between each other.

In applications where multiple hydraulic pumps are used, Kawasaki K3VL hydraulic pumps are ideal as motors can be connected in parallel and shared power between each other.

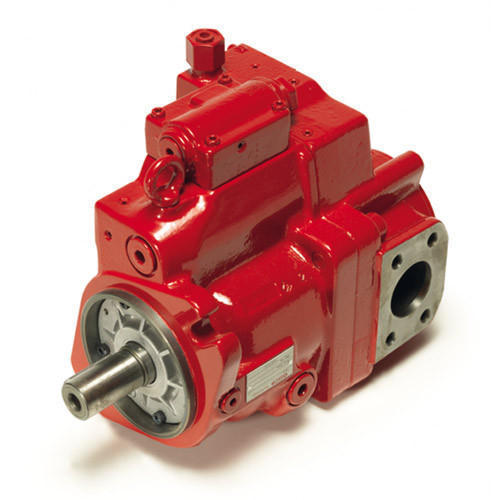

A Kawasaki K3VL hydraulic pump has been designed to be used in a variety of industrial applications. It is suitable for use in agricultural machinery and construction equipment. The hydraulic pump is also ideal for use in marine vehicles, like fishing trawlers or cargo ships.

In addition to these applications, Kawasaki K3VL hydraulic pumps can be used in mining equipment or oil platforms. These types of equipment require heavy-duty components that can withstand the harsh conditions found at sea or on land.

At low speeds, the K3VL hydraulic pump is set to slow down the engine while still providing enough power to run the equipment.

The Kawasaki K3VL hydraulic pump is equipped with a variable displacement feature that allows it to change its displacement rate according to the load on the engine. The amount of oil displaced by the piston changes in response to the engine’s load requirements. This gives you more power when you need it and less when you don’t. This also helps reduce fuel consumption and emissions.

De Kawasaki K3VL Pump is designed to operate in systems that do not require full-time maximum flow, such as automatic transmissions.

Features

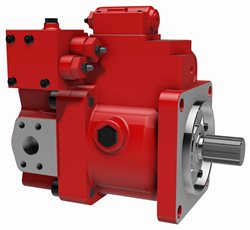

The Kawasaki piston pump has a centrifugal lobe pump design and provides reliable performance at an economical price. The unit has two-stage ports allowing it to be used in systems with large pressure drops at low flows. The piston pump can be operated with no lubrication or water cooling, or with a separate oil supply and water coolant supply. It can be mounted on either side of the engine, which allows greater flexibility in mounting position to accommodate varying installation requirements.

Applications

Kawasaki piston pumps are used for power steering, air conditioning and other hydraulic applications requiring a compact size and high pressure capability over a wide range of flow rates.

These types of Hydraulic Pumps have great flexibility in reducing care costs with their advanced control techniques.

These types of Hydraulic Pumps have great flexibility in reducing care costs with their advanced control techniques. The Kawasaki K3VL Hydraulic Pump is a very useful product that helps the user to get a smooth and efficient working experience. It helps in controlling the flow of oil in a machine or any other equipment that uses oil for its operations. The pump can be used in many different industries such as automobile, manufacturing, construction, farming and more.

The Kawasaki K3VL Hydraulic Pump has excellent durability with its high quality materials and components that make it last for a long time without breaking down easily. The pump also has an automatic shut off feature which allows it to stop working if there are any issues with the engine or any other component that makes up the hydraulic system. This can help prevent further damage from occurring which will lead to more expenses for repairs or replacements of parts.

In summary, the Kawasaki K3VL pump does have a few shortcomings. To name a few, it does not feature hot start or built in priming means. However, for most homeowners these are not likely to be major issues. All things considered, this is an excellent pump that should serve its owners well.