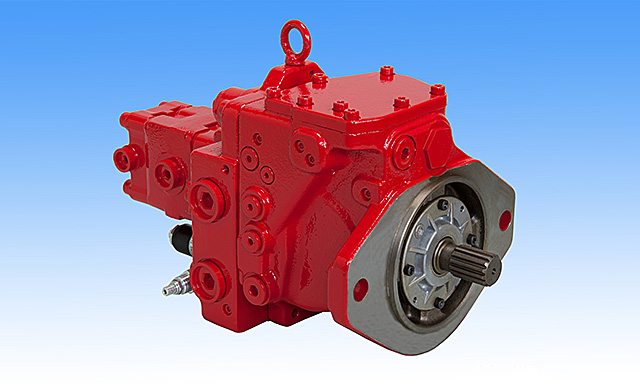

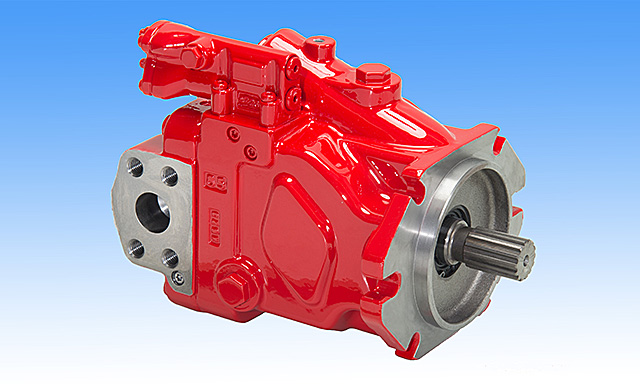

VH01 skovelpumpar och VH02 skovelpumpar från Vickers

The VH01 and the VH02 pumps were developed in the early 1950s to meet the growing demand for low pressure vacuum systems. The pump is designed to handle liquids or gases and has a wide range of applications including medical, pharmaceutical and analytical instruments.

The VH01 is a single-stage axial-flow pump with an external rotor. It has a pre-lubricated ball-bearing rotor with no seals or lubricants inside the pump. The only lubrication required is at the bearings, which are located outside the pump housing. This unique design eliminates the need for internal seals, making it ideal for process fluids that may be corrosive or contain particulate matter such as abrasives or silica dust.

The VH02 is a two-stage axial-flow centrifugal pump with an external rotor. It is also pre-lubricated with no seal or lubricant inside the pump housing so it can handle corrosive fluids without any problems. The only lubrication required is at the bearings which are located outside the pump housing just like on our other centrifugal pumps

De Vickers VH01 vane pumps and Vickers VH02 vane pumps are similar pumps.

The VH01 and VH02 are similar pumps. They have the same motor, pump head and housing, but different impellers. The VH01 is a high pressure (HP) vane pump, while the VH02 is a low pressure (LP) vane pump. The HP version has a maximum inlet pressure of 9 bar (150 psi) and maximum flow rate of 8 l/min at 3 bar (50 psi). The LP version has a maximum inlet pressure of 4 bar (60 psi) and maximum flow rate of 6 l/min at 2 bar (30 psi).

The VH01/VH02 has been designed specifically as an external vane type pump for use in harsh environments such as chemical handling, power generation and oil extraction applications where large amounts of contaminated water need to be handled quickly without risk of contamination being transferred back into the process stream.

The pump is capable of handling fluids with temperatures ranging from -10°C up to +80°C or higher if suitable heat exchange fluid is used. It can also run dry without lubrication if required.

The VH01 vane pump is designed for applications where a high slow speed is required.

The VH01 vane pump is designed for applications where a high slow speed is required. The pump has the ability to operate at up to 10Hz. The VH01 is suitable for use in the food, chemical, pharmaceutical and dairy industries as well as in many other applications.

The VH02 vane pump is designed for applications where a high washdown rating is required. The pump has the ability to operate at up to 10Hz. The VH02 is suitable for use in the food, chemical, pharmaceutical and dairy industries as well as in many other applications.

The VH02 vane pump is similar to the VH01 with the exception that it has a higher speed rating, a lower displacement and requires less input horsepower than the VH01.

The VH02 vane pump is similar to the VH01 with the exception that it has a higher speed rating, a lower displacement and requires less input horsepower than the VH01.

The VH02 vane pumps are designed for use in applications such as water supply systems and industrial process applications. They can also be used to provide water pressure for fire protection systems such as sprinklers, standpipes and emergency showers.

The VH02 vane pump uses two or four vanes with an external rotor mounted on ball bearings that provides maximum efficiency at low speeds. The outer rotor is supported by an internal stator with a row of stator vanes that create hydraulic force when rotating in the same direction as the outer rotor. This enables fluid transfer from one side of the pump to the other without using seals or stuffing boxes.

The pumps use two or three vanes depending on the model.

The VH01 vanes are made from hardened steel, which makes them more durable than other types of vane materials. The VH02 vanes have a stainless steel body with a chrome plated surface for corrosion resistance.

Vickers also offers several valves for these pumps, including check valves for pressure relief and back flow prevention, ball valves for flow control and butterfly valves for directional control.

The company also makes a variety of accessories to help you install your new pump system properly. These include mounting brackets and feet as well as bypass unions and suction cups to secure your equipment while it’s being installed.

Low cost, long life and rugged construction are hallmarks of these pumps.

The VH01 is a vane pump that has been designed for use in a wide variety of applications. This pump can be used for liquids that contain suspended solids and/or abrasive materials, such as paints, adhesives, inks and thinners. The VH01 is also suitable for use with water soluble materials such as oils and glycols up to 60% concentration.

The VH02 is a vane pump that has been designed for use in a wide variety of applications. This pump can be used for liquids that contain suspended solids and/or abrasive materials, such as paints, adhesives, inks and thinners. The VH02 is also suitable for use with water soluble materials such as oils and glycols up to 60% concentration.

Vickers VH01 vane pumps and Vickers VH02 vane pumps are useful in a variety of applications.

Both pumps are useful in a variety of applications. The VH01 is designed to be submerged in water and the VH02 is designed to be used in air.

The VH01 can operate at up to 2,000 RPM with a flow rate of up to 1,200 GPM. It uses three vanes that are made from high carbon steel and can handle temperatures up to 450 degrees Fahrenheit. It has a maximum pressure rating of 5,000 PSI and a maximum vacuum rating of -30 PSI. The pump weighs about 200 pounds and is rated for continuous operation at full capacity.

The VH02 has two vanes that are made from high carbon steel and can handle temperatures up to 450 degrees Fahrenheit. It also has a maximum pressure rating of 5,000 PSI and a maximum vacuum rating of -30 PSI. The pump weighs about 100 pounds and is rated for continuous operation at full capacity

The Vickers VH01 vane and VH02 vane pumps are advanced designs in comparison to the conventional gear driven pump. The VH series of pumps allows for operation at much higher operating speeds than a gear pump, which is suitable for applications where flow cannot be compromised. For high pressure applications, the vane pump is an appropriate choice over the gear pump.