Most of us probably wonder how the largest excavators in the world look like and it is only natural – we all want to know what it is like to operate such large machines which are capable of demolishing almost any earth structure in a single pass. But not all of us are capable of climbing inside such giants and see for ourselves. So, let’s see if we can change that by taking a closer look at 14 biggest trucks in the world.

The largest excavator main application

In addition to the relative small excavator, there is also a large excavator. Of course, this large-scale excavator for some special occasions to use.

•The first application is the open-pit mining. This is what we often say that the open-pit mining. The main purpose of this work is to dig out the ore from the pit. For example, in the mine iron ore mining and mining machinery in general, for example, you can look at some large-scale copper mine, which are generally used in large-scale open-pit mining equipment. To achieve this work, there must be a lot of workers working together with large construction machinery. For example, there may be a truck with a dump truck or a loader that will be used to load the excavated ore into a truck or train. These are very common scenes in large open pits.

•Another major application of excavation machinery is widely used in road construction projects and civil engineering projects such as tunnels and bridges. For example, if you want to build a tunnel or bridge, then it is necessary to use this kind of equipment to dig out some soil and stone materials needed for bridge and tunnel construction.

What are the limitations of the largest excavator?

As a result of the limitation of the physical properties of the mechanical equipment, the largest excavator is also restricted. First of all, it is limited by its own weight, which is limited by its own load-bearing capacity. The larger the size of the excavator, the greater the weight, and then the greater the load-bearing capacity required for the carrier.

In addition to these two factors, another important factor is that it is limited by its own working range, namely extending to how far away from itself. In terms of working range, it can be divided into two types: one is a single boom excavator, and a multiple boom excavator. The former has only one arm in front of it and cannot be extended sideways; while multiple arm excavators can stretch horizontally in both directions.

The above are some of the limitations on large excavators. However, with technological advances today, large excavators are becoming more and more powerful.

What are the advantages of the largest excavator?

Characteristics of large mining machinery

1. powerful

The power system of Terex mining machinery is a type of structure with high reliability, high safety level, high efficiency and energy saving, low noise, strong adaptability and strong overload capacity. The main engine uses a six-cylinder electronic control turbocharged diesel engine, which has a large power reserve, easy starting performance at low temperature, and can achieve 100% load power output under standard working conditions.

2. High efficiency

The high-efficiency hydraulic system and working device system of Terex mining machinery greatly improve the loading speed of the bucket and improve the working efficiency of the machine. The hydraulic system adopts parallel valve control technology to improve work efficiency by 20%. For example, the loading speed of a 7m3 bucket can reach 1.2m/s; compared with similar products in China, it can load more than 500 buckets per hour.

3. Low noise

The engine adopts an integrated turbocharger muffler to reduce exhaust noise; the fuel tank adopts a new baffle design, effectively reducing fuel sloshing noise. The cab’s anti-vibration design reduces noise, and the laminate is used for internal sound insulation, achieving low noise.

I tell about the top 14 largest excavators in the world.

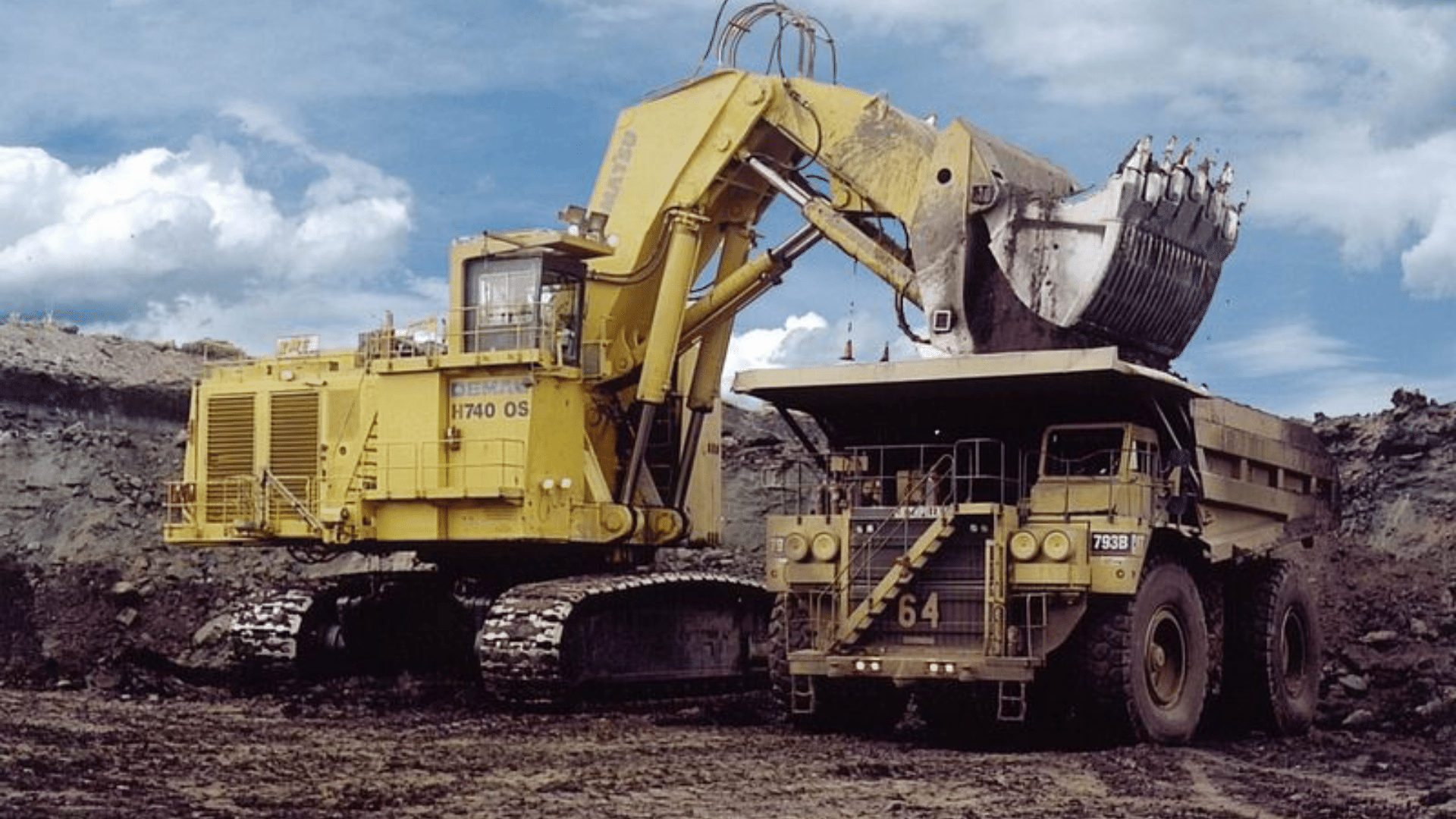

Demag H740 OS excavator

The Demag H740 OS excavator, created by the German company Krupp for the power industry, is a machine designed to operate under the toughest conditions. The Demag H740 OS excavator features a 744 horsepower engine that can operate at 2,300 revolutions per minute. Designed for use in large scale civil engineering projects where huge volumes of earth have to be moved, the Demag H740 OS excavator has a maximum bucket size of 52 cubic meters and an operating weight of 744 tons.

The Demag H740 OS excavator provides its power from a V16 MTU diesel engine. It has an operating speed of 2 km/h with a max speed of 4 km/h and can climb up gradients with ease. This allows it to work on rough terrain easily and efficiently.

The Demag H740 OS excavator is a powerful mining machine used for open pit mining operations. It’s also used for oil sands mining where its large size makes it useful for moving significant amounts of earth. The heavy-duty hydraulic system and innovative design make it a great choice for contractors looking to maximize productivity while reducing costs.

| Weight | 744 t |

| Bucket capacity | 40 m³ |

| Tear-out force | 2320 kN |

| Engine manuf | Caterpillar |

| Engine type | 3516B DITA (2x) |

| Engine power | 3280 kW |

| Revolutions at max torque | 1800 rpm |

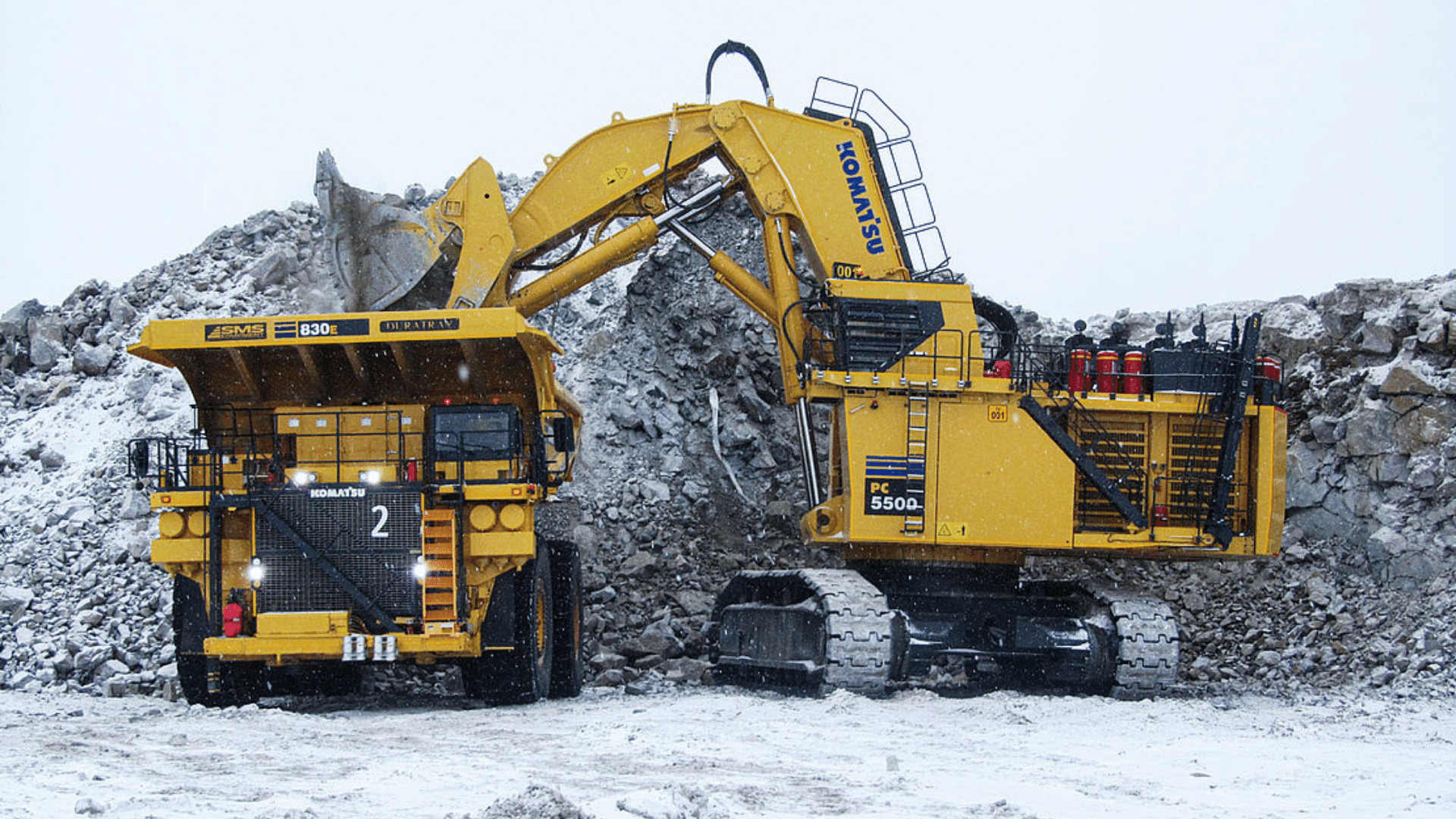

Komatsu PC5500-6 excavator

The Komatsu PC5500-6 excavator is a large production sized machine that can be used for some of the most difficult jobs. Able to move over thirty-five metric tons, the Komatsu PC5500-6 offers an operating weight of seventy-six metric tons with a bucket capacity of fifteen cubic meters.

The Komatsu PC5500-6 excavator also offers optimal engine performance thanks to its high pressure fuel injection system and turbocharging after cooling capability. The engine functions quietly and smoothly while providing excellent combustion efficiency and low emission levels.

The Komatsu PC5500-6 excavator’s hydraulic system provides maximum hydraulic efficiency through the use of two variable displacement pumps. The hydraulics on this model are designed to provide smooth, powerful action for all movements, including arm and boom actions.

Built with operator comfort in mind, the Komatsu PC5500-6 excavator features a spacious cab with adjustable arm rests, an ergonomically designed control panel, and an automatic climate control system that maintains a comfortable temperature in any weather conditions. This model also offers noise reduction capabilities thanks to its three layer roof construction and sound absorbing material in the cab doors and floors.

| Komatsu PC5500-6 excavator | parameter |

| Operating Weight – Backhoe | 1186300 – 1217200 lb(538097 – 552113 kg) |

| Operating Weight – Loading Shovel | 1203900 lb (546080 kg) |

| Max Bucket Capacity (SAE heaped) – Backhoe | 38 yd3(29 m3) |

| Bucket Capacity (SAE heaped) – Loading Shovel | 38 yd3(29 m3) |

| Max Digging Depth – Backhoe | 27′3″ (8300 mm) |

| Max Digging Depth – Loading Shovel | 8′10″ (2700 mm) |

| Max Dump Height | 33′2″ (10100 mm) |

| Max Dump Height – Loading Shovel | 43′8″ (13300 mm) |

| Max Bucket Breakout Force (ISO) | 340750 U.S. tons (154,562 kN) |

| Max Arm Digging Force (ISO) | 298050 U.S. tons (135,193 kN) |

| Max Arm Digging Force – Loading Shovel | 208 lb (1850 kg) |

| Arm Length | 36′1″ (11000 mm) |

| Track Width | 53′ – 71′(1350 – 1800 mm) |

| Ground Pressure | 26.5 – 34.5 psi(182.7 – 238 kPa) |

| Travel Speed | 1.4 mph (2.1 kmh) |

| Ground Pressure – Loading Shovel | 34 psi (234 kPa) |

| Te faaoreraa i te mau haamâu' | Tier 2 |

| Make / Model | Komatsu SDA12V159E-2 |

| Gross Horsepower | 1260 HP @1,800 rpm (940 kW @1,800 rpm) |

| Engine Lubrication | 50 U.S. gal (190 L) |

| Cooling System | 95 U.S. gal (360 L) |

| Fuel Tank Capacity | 2736 U.S. gal (10355 L) |

Liebherr R9800 excavator

The R9800 is Liebherr’s largest excavator, weighing in at 800-tonne. Its diesel engine generates 6960kW of power and the vehicle has a bucket capacity of 36m3.

The R9800 is powered by a Liebherr 12-cylinder, turbocharged diesel engine. It produces 6960kW at 1800 revolutions per minute (rpm). The machine has a maximum torque of 8850Nm at 1300rpm and an operating weight of 710 tonnes (depending on the specification). The crawler tracks are 60m long, 3.5m wide and 1.1m high.

The Liebherr R9800 is equipped with a 16-cylinder diesel engine that produces 10,500HP. It also features a standard bucket size of 13m3 and an operating weight between 710t and 870t depending on the variant.

Liebherr engineers have developed the R9800 to be easily transportable to any mine site. Its size means it can be transported in sections on a specialist low-loader trailer and assembled on site using basic tools.

| Engine model | 2x Cummins QSK 60 |

| Engine rating at 1800 rpm | 2,984 kW |

| Emissions (USA/EPA) | Tier 2 / US EPA Tier 4f / EU Stage V |

| Engine model (option A) | 2x Liebherr D9812 |

| Engine rating at 1800 rpm (option 2) | 3,000 kW |

| Emissions (USA/EPA) (option 2) | US EPA Tier 4f / EU Stage V |

| Electric motor (option) | Available |

| Attachment and travel drive pump | 10 variable flow axial piston pumps x 750 l/min. @ 320 bar |

| Swing drive pump | 4 reversible swash plate pumps x 535 l/min. @ 320 bar, closed-loop circuit |

| Maximum swing speed | 3.60 rpm |

| Operating weight with backhoe attachment | 800.00 t |

| Bucket capacity at 1.8 t/m³ | 47.50 m³ |

| Max. digging force (ISO 6015) | 1,760 kN |

| Max. breakout force (ISO 6015) | 1,980 kN |

| Operating weight with face shovel attachment | 810.00 t |

| Shovel capacity at 1.8 t/m³ | 42.00 m³ |

| Max. crowd force at ground level (ISO 6015) | 2,945 kN |

| Max. crowd force (ISO 6015) | 3,090 kN |

| Max. breakout force for shovel (ISO 6015) | 2,395 kN |

Bucyrus RH 340/RH 340-B excavator

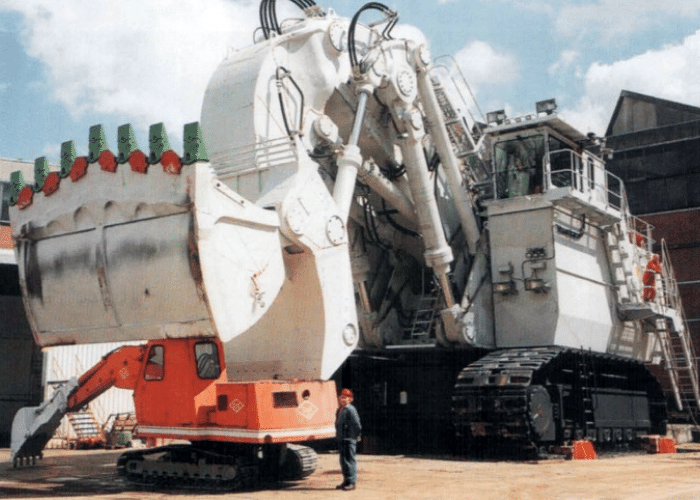

The Bucyrus RH 340/RH 340-B hydraulic mining excavator is the largest mining shovel in the world, with a shovel capacity of 62 cubic meters. The Bucyrus RH340/RH340-B was originally designed as a coal mining machine, but can be used effectively to mine other minerals.

The Bucyrus RH340/RH340-B is powered by two Caterpillar 3616 diesel engines that produce 4,700 horsepower (3,500 kW) each. These diesel engines are V16 engines that each have a displacement of 16,122 cubic centimeters. The air cleaner for each engine is located behind the cab and has a diameter of 1 meter (3.3 feet). Each engine has an oil pan that has a capacity of 1,136 liters (300 gallons).

Each engine drives one drum on the main hoist through a clutch and torque converter. The power from each drum goes to the swing mechanism via a gear box. The swing mechanism can turn 360 degrees and can rotate at 3 revolutions per minute. The hoisting drums on each side of the crane can raise and lower at rates up to 32 meters per minute (105 feet per minute).

| Max Dig Depth | 29.2ft in |

| Max Cutting Height | 52.17ft in |

| Backhoe Boom / Stick | boom 34’5″ (10500mm) w/ stick 16’5″ (5000mm) |

| Width Over Tracks | 22.97ft in |

| Length Of Track On Ground | 23.27ft in |

| Height To Top Of Cab | 28.78ft in |

| Ground Clearance | 3.68in |

| Length Of Tracks | 30.29ft in |

| Height Of Tracks | 8.21ft in |

| Upper Structure Ground Clearance | 9.16ft in |

| Max Dig Reach | 53.48ft in |

| Max Dump Height | 37.73ft in |

| Max Cutting Height | 50.53ft in |

| Max Dig Depth | 8.54ft in |

| Loading Shovel | boom 26’2″ (8000mm) w/ stick 16’9″ (5100mm) |

| Track Gauge | 18.38ft in |

| Loading Shovel Ground Pressure | 30.7psi |

| Max Travel Speed | 1.25mph |

| Engine Model | 2 x K 1500-E |

| Net Power | 2520hp |

| Gross Power | 2520hp |

| Power Measured @ | 1800rpm |

| Displacement | 2300cu in |

| Aspiration | Turbocharged and aftercooled |

| Fuel Capacity | 2826.7gal |

| Hydraulic System Fluid Capacity | 1611.5gal |

| Swing Speed | 3.9rpm |

| Operating Voltage | 24V |

| Alternator Supplied Amperage | 350amps |

| Reference Bucket Capacity | 36.7yd3 |

| Maximum Bucket Capacity | 44.5yd3 |

Hitachi EX5600-6 excavator

The EX5600-6 excavator from Hitachi Construction Machinery is designed for large-scale mining applications, with an operating weight of 571,000 to 594,500 pounds (259,500 to 269,900 kg). The hydraulic excavator features an EPA Tier 4 Final/EU Stage IV certified Isuzu engine that produces 1,805 horsepower (1,343 kW). The machine can be used in ultra-class mining applications such as overburden removal and production loading.

The Hitachi EX5600-6 excavator is powered by a 16-cylinder turbocharged Isuzu engine capable of producing 1,805 horsepower.

The Hitachi EX5600-6 has a standard bucket capacity of 29 cubic yards (22 cubic meters) and a 44.3 cubic yard (33.9 m3) capacity in backhoe operations. The machine can also transport up to 530 tons (238 metric tons) of material at a time with the addition of a rear dump body or haul truck attachment.

| NET POWER | 2 x 1119kw/1,500HP |

| OPERATING WEIGHT | 549,000kg |

| Backhoe | 1,210,338lbs |

| Shovel | 544,000kg |

| MAX DIG REACH | 20.2m |

| Backhoe | 66ft3in |

| Shovel | 17m 55ft9in |

| MAX DIG DEPTH | 8.8m |

| Backhoe | 28ft11in |

| Shovel | 4.8m |

Komatsu PC8000-6 excavator

The Komatsu PC8000-6 excavator is a massive, ultra-class mining excavator that can move thousands of cubic meters of material per hour. It’s used in open pit mines across the world for coal and other minerals, as well as iron ore, gold and copper.

The Komatsu PC8000-6 excavator is one of the largest excavators in the world. It weighs more than 1.5 million pounds (680 tonnes) and has a shovel capacity of 62-72 m3. In addition to being used as an excavator, it can also be used as a wheel dozer or wheel loader depending on its attachments.

The Komatsu PC8000-6 is built to handle any job you throw at it. The massive size and strength of this machine is perfect for any application where there is a need for heavy lifting or moving large objects like boulders or rocks.

With a length of almost 24feet (7 meters) and height over 10feet (3 meters), the PC8000-6 has a lot of surface area to work with. It’s also very heavy: fully loaded with fuel, supplies and crew members onboard.

| Weight | 777 t |

| Transport length | 14.078 m |

| Transport width | 10.01 m |

| Transport height | 9.655 m |

| Bucket capacity | 42 m³ |

| Undercarriage | HD |

| Track width | 1900 mm |

| Max. Reach horizontal | 20.7 m |

| Dredging depth | 8 m |

| Tear-out force | 1800 kN |

| Bucket width | 4.575 m |

| Engine manuf | Komatsu |

| Engine type | SDA16V160E-2 (2x) |

| Engine power | 3000 kW |

Caterpillar 6090 FS excavator

The Caterpillar 6090 FS excavator is a mining machine that weighs in at 558,000 pounds and has the ability to dig at depths of up to 41 feet. The machine is powered by a 3408C diesel engine, which produces 870 horsepower. It is capable of digging 6,000 cubic yards of material per day.

The Caterpillar 6090 FS excavator has two engine cooling fans and an air conditioning unit that are independent of each other. This allows the operator to control when the fans and AC unit run.

The front window on the Cab is made of bulletproof glass and can be opened to allow fresh air in while the vehicle is in motion.

The Caterpillar 6090 FS excavator has a 360 degree camera system that allows the operator to see around the entire perimeter of the vehicle while operating it remotely.

| Weight | 1000 t |

| Transport length | 13.53 m |

| Transport width | 9.72 m |

| Transport height | 9.99 m |

| Bucket capacity | 52 m³ |

| Track width | 2000 mm |

| Max. Reach horizontal | 19.3 m |

| Dredging depth | 2.6 m |

| Tear-out force | 2502 kN |

| Bucket width | 6.1 m |

| Engine manuf | Cummins |

| Engine type | QSK60 (2x) |

| Engine power | 3360 kW |

| Displacement | 60.2 l |

| No. of cylinders | 16 |

| Cylinder bore x stroke | 159×190 mm |

| Emission level | U.S. EPA Tier 2 |

Bucyrus RH400 excavator

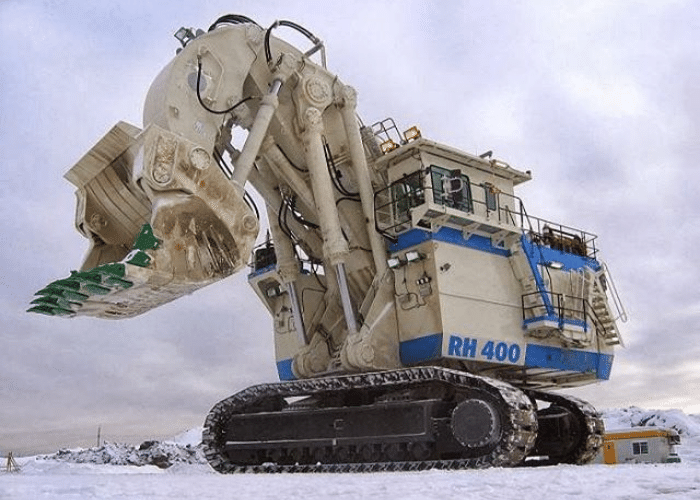

The Bucyrus RH400 excavator, weighing approximately 889t, is the world’s biggest hydraulic excavator. It was launched by Komatsu America Corp in USA in May 2008 and is currently being used by Caterpillar Global Mining at the Buck Creek coal mine in the US state of Indiana.

The Bucyrus RH400 excavator was developed for use in large open pit mining operations under extremely harsh conditions. The size of this model allows it to move up to 63,000m3 of material per day, which is more than a mining truck can haul in several days.

The RH400 operates on electric power and is powered by two 16-cylinder diesel engines that produce 5,500HP. In order to move the machine, four wheel drive and four wheel steering is used with an electro-hydraulic control system and automatic traction control.

The Bucyrus RH400 has a standard bucket capacity of 50m3 and an operating weight of 1,150t when fully equipped with crew and lubricants.

Bucyrus International acquired the mining division from Terex Corporation on 1 July 2010, forming Bucyrus International Inc. The company was renamed Komatsu America Corp in 2013 as part of its acquisition by Komatsu Limited.

| Width Over Tracks | 28.22ft in |

| Length Of Track On Ground | 27.71ft in |

| Height To Top Of Cab | 33.39ft in |

| Ground Clearance | 3.73in |

| Length Of Tracks | 36.03ft in |

| Upper Structure Ground Clearance | 10.34ft in |

| Height Of Tracks | 9.67ft in |

| Max Dig Reach | 62.34ft in |

| Max Dump Height | 47.58ft in |

| Max Cutting Height | 66.28ft in |

| Max Dig Depth | 7.55ft in |

| Loading Shovel | boom 31’2″ (9500mm) w/ stick 18’4″ (5600mm) |

| Loading Shovel Shoe Width | 78.75in |

| Track Gauge | 21.66ft in |

| Loading Shovel Ground Pressure | 30.7psi |

| Max Travel Speed | 1.37mph |

| Engine Make | 2347 |

| Engine Model | 2 x QSK 60-C |

| Net Power | 4500hp |

| Gross Power | 4500hp |

| Power Measured @ | 1800rpm |

| Displacement | 4210cu in |

| Aspiration | Turbocharged and aftercooled |

| Fuel Capacity | 4226.8gal |

| Hydraulic System Fluid Capacity | 2641.8gal |

| Swing Speed | 4.4rpm |

| Operating Voltage | 24V |

| Alternator Supplied Amperage | 350amps |

| Reference Bucket Capacity | 58.9yd3 |

Hitachi EX8000-6 excavator

Hitachi EX8000-6 is the world’s largest hydraulic excavator. It is the sixth generation of Hitachi’s EX8000 series.

The EX8000-6 features a newly developed cab, a completely redesigned upper structure, and a new undercarriage frame. Hitachi engineers have achieved weight reduction by 132t and increased production by 10% compared to its predecessor, the EX8000-5.

The machine has an operating weight of 810t and a shovel capacity of 45m³. It can be configured with either a 45m³ backhoe or 20m³ shovel attachment. The machine is powered by two 20-cylinder diesel engines with a combined output of 8,300kW (11,080hp).

The EX8000-6 has been designed for heavy earthmoving applications in major mining sites such as iron ore and coal pits in Australia and South America.

| Model Code | EX8000-6 |

| Engine Rated Power (kW) | (kW)2x 1 450 kW (2x 1 940 HP) |

| Operating weight (kg) | 811 000 kg |

| Backhoe Bucket ISO Heaped | Heaped38.0 – 43 m³ |

| Max. digging depth (mm) | 13 800 mm |

| Bucket digging force (kN) | ISO2 230.0 |

Liebherr R996 B excavator

The Liebherr R996 B excavator is a leader in the field of large hydraulic excavators. The R996 B combines all the qualities that have made Liebherr famous: robustness, reliability, high performance and outstanding efficiency. These combined with maximum safety for the operator and the environment make this hydraulic excavator an excellent choice for all types of applications.

The Liebherr R996 B is built on a 6-axle chassis with a rear axle that can be steered hydraulically or mechanically. The machine has a robust design with high quality components, which enables it to operate reliably and economically under any conditions.

The Liebherr R996 B is a 1000 kW/1360 HP electric excavator with a standard bucket capacity of 9.6 m³ and can handle up to 20 metric tons (22 US tons). The maximum operating weight of the machine is 300 metric tons (330 US tons). With these features it is the ideal choice for any application requiring high production rates at low cost per tonne.

| Weight | 672 t |

| Bucket capacity | 36 m³ |

| Track width | 1400 mm |

| Boom | MB |

| Max. Reach horizontal | 19 m |

| Dredging depth | 8,11 m |

| Tear-out force | 1500 kN |

| Engine manuf | Cummins |

| Engine type | K1800E (2x) |

| Engine power | 2240 kW |

| Displacement | 50.3 l |

| Revolutions at max torque | 1800 rpm |

Komatsu PC7000-11 excavator

The PC7000-11 shovel excavator is designed to work in large scale open pit mines. Its bucket capacity of 32 cubic meters is the largest in the world, exceeding by nearly 10% the previous record holder.

The machine is powered by a Komatsu SDA24V160E-2 diesel engine delivering 6,250 horsepower (4,650 kW). It has a maximum drawbar pull of 3,900 kN and weighs 1,500 tons. The PC7000-11 is 53 meters long and 13 meters wide over the tracks.

The shovel reaches a depth of 17 meters below ground level and a height of 20 meters above ground level. The boom itself has a length of 21 meters and uses a hydraulic cylinder system to balance its weight without putting too much stress on the undercarriage.

| Model | 2 x Komatsu SSDA16V159E-2 Tier 2 |

| Type | 4-cycle, water-cooled, direct injection |

| Aspiration | Turbocharged and aftercooled |

| Number of cylinders | 16 |

| Rated power @ 1,800 rpm (SAE 1995/J1349) | 2 x 1,675 HP |

| Governor | All-speed, electronic |

| System | 24 V |

| Batteries (series/parallel) | 8 x 12 V |

| Alternator | 2 x 140 A |

| Standard working lights | 16 LED lights |

| Standard service lights | throughout platform incl. emergency egresses and stairways |

| Track adjustment | Automatic hydraulic type |

| Number of track shoes | 49 each side |

| Number of top rollers | 3 each side |

| Number of bottom rollers | 7 each side |

| Travel control | 2 foot pedals |

| Gradeability | Up to 50% |

| Travel speed (maximum) | 1.55 mph |

| Service brake | Hydraulic brake |

| Parking brake | Wet, multiple-disc |

| Type | 2 x Squirrel cage induction motor |

| Power output | 2 x 1,200 kW |

| Voltage | 6,000 – 7,200 V* |

| Amperage (approximate) | 2 x 128 A – 2 x 107 A |

| Start-up | Soft start each motor in succession |

| Frequency standard | 60 Hz @ 1,800 rpm |

| Frequency option | 50 Hz @ 1,500 rpm |

| Hydraulic oil tank | 1,255 US gal |

| Hydraulic system | 2,510 US gal |

| Fuel | 3,443 US gal |

| Engine coolant | 2 x 116 US gal |

| Engine oil | 2 x 62 US gal |

| Reserve engine oil make up tank | 2 x 176 US gal |

Caterpillar 6060 excavator

The new Caterpillar 6060, 6060 FS and 6060 HR excavators are powered by a 1,450-hp, Caterpillar 3412E engine. The machines have a top speed of 21.5 mph and use a hydraulically driven fan with a transmission-driven clutch for cooling.

The Cat 6060 family has a standard breakout force of 160,000 pounds and drawbar pull of 220,600 pounds. Maximum digging depth is 33 feet, 9 inches, and maximum reach at ground level is 54 feet, 10 inches.

A bucket rotation lock system can be used to improve control and accuracy during fine grading operations. A low-effort control lever provides smooth loader operation when moving material into trucks or hoppers and has three modes: high sensitivity for fine work; precision for normal work; and heavy for high inertia loads such as large rocks.

The John Deere 6060 chainsaw is a high-performance saw designed for heavy-duty use. It’s built tough, with all-steel parts that are welded together to ensure durability. The saw has an ergonomic handle and trigger guard so you can hold it comfortably, while the aluminum body makes it lightweight at just 8.8 pounds. With a powerful 24-inch bar length (24-inches) and 0.404-inch pitch chain size (0.404 inches), it cuts through wood up to 22 1/2 inches in diameter or 22 1/2 inches in circumference at full throttle when used as recommended by its manufacturer.”

| Engine Output – SAE J1995 | 3023 HP |

| Bucket Payload | 67 ton (US) |

| Te faito kilo | 660 ton (US) |

| Rated Speed | 1,800 min-1 (1,800 rpm) |

| Bore | 6.69 in |

| Stroke | 8.46 in |

| Displacement | 3574 in³ |

| Gross Power – SAE J1995 | 3023 HP |

| Net Power – ISO 9249 | 2995 HP |

| Net Power – SAE J1349 | 2977 HP |

| 6060 FS – Standard Track Pads | 4.58 ft |

| 6060 FS – Operating Weight | 1320110 lb |

| 6060 FS – Ground Pressure | 26.6 N/cm2 (38.5 psi) |

| Backhoe – Standard Track Pads | 4.58 ft |

| Backhoe – Operating Weight | 1323860 lb |

| Backhoe – Ground Pressure | 26.7 N/cm2 (38.7 psi) |

| Main Pumps – Diesel Version | 8 variable swash plate pumps |

| Main Pumps – Maximum Oil Flow – Diesel Version | 8 x 650 L/min (8 x 172 gal/min) |

| Maximum Pressure – Attachment | 4640 psi |

| Maximum Pressure – Travel | 5220 psi |

| Swing Pumps – Diesel Version | 4 reversible swash plate pumps |

| Swing Pumps – Maximum Oil Flow – Diesel Version | 4 x 352 L/min (4 x 93 gal/min) |

| Maximum Pressure – Swing Pumps | 5075 psi |

| Operator’s Eye Level – Approximately | 24.91 ft |

| Internal Dimensions of Cab – Length | 7.33 ft |

| Internal Dimensions of Cab – Width | 5.33 ft |

| Internal Dimensions of Cab – Height | 6.75 ft |

MAN TAKRAF RB293 excavator

The MAN TAKRAF RB293 is a giant bucket-wheel excavator made for the energy and surface mining industries.

MAN TAKRAF RB293 bucket-wheel excavator at Garzweiler surface mine, Germany.

The MAN TAKRAF RB293 is a giant bucket-wheel excavator made for the energy and surface mining industries. It was built by the German company MAN Takraf, formerly known as VEB TAKRAF.

The MAN TAKRAF RB293 is one of the ten biggest machines in world.

This machine weighs 14,200 tons, has a length of 220 metres (720 ft), width of 96 metres (315 ft), height of 95 metres (312 ft) and a digging depth of up to 45 metres (148 ft).

| Length | 225 m (738.2 ft) |

| Width | 46 m (151 ft) |

| Height | 96 m (314.9 ft) |

| Weight | 14,200 t (31,300,000 lb) |

| Propulsion | 12 x caterpillar tracks |

| Gross power | 16.56 megawatts of externally supplied electricity |

| Speed | 2 to 10 m (6.6 to 32.8 ft) per minute (0.1 to 0.6 km/h) |

Caterpillar 7495 HF excavator

Caterpillar 7495 HF excavator The Cat® 7495 HF hydraulic mining shovel is a front-shovel loader with a nominal payload of 91.5 tonnes (101 tons). With an operating weight of 740 tonnes (813 tons), the 7495 HF is designed to load haul trucks up to 400 tonnes (440 tons) in size.

It has long been recognised that the high stripping ratio at an open cut mine and the loading of large tonnage trucks are two of the most productive areas for improvement. The continued development of both equipment and mining methods has meant that open pit mines are able to handle these larger haul trucks, and these trucks require equally large excavators to match. As these excavators have increased in size, so too has their fuel consumption.

Caterpillar’s fully integrated AC electric drive system provides lower fuel consumption through reduced engine power, improved gear efficiency and advanced control strategies. Electrically driven components are more efficient than traditional hydraulics, with all the energy generated by the engine being used to move material rather than waste heat from the hydraulics.

| Dipper Payload | 120 t |

| Dipper Capacity | 30.6-62.7 m3 (40-82 yd3) |

| Working Weight – With Dipper and Standard Links | 3164000 lb |

| Ballast – Furnished By Customer | 667150 lb |

| Crawler Dimensions – Overall Width 317.5 cm (125 in) Treads | 41.67 in |

| Upper Works Overall Width – Including Standard Walkways | 41.99 in |

| Ground Bearing Pressure | 57 m2 (248 kPa); 614 ft2 (36 psi) |

| Drive | IGBT Acutrol drive system |

| System Voltage – Nominal | 50/60 Hz, 7,200V |

| Power Requirements – Voltage | 3 phase, 50/60 Hz, 7,200V |

| Note | Other voltage options available to suit customer requirements |

| Power Requirements – 50 Hz | 6,000V, 6,600V, 7,200V, 11,000V |

| Power Requirements – 60 Hz | 7,200V, 13,800V |

| Power Requirements – Peak power | 3778 kW |

| Power Requirements – Average Power Demand | 945-1322 kW |

| Rope Data – Note | High impact ropes available as an option |

| Rope Data – Hoist – No. | 2 |

| Rope Data – Hoist – Diameter | 2.75 in |

| Rope Data – Dipper Trip – No. | 1 |

| Rope Data – Boom Suspension – Diameter | 3.25 in |

| Rope Data – Dipper Trip – Diameter | 0.75 in |

| Rope Data – Boom Suspension – No. | 4 |

| Te faito kilo | 3164000 lb |

| Dipper Payload | 120 ton (US) |

| Maximum Dumping Height | 29.53 ft |

| Dipper Capacities | 30.6-62.7 m3 (40-82 yd3) |

| Radius of Level Floor | 55.77 ft |

| Cutting Height – Maximum | 55 ft |

| Dumping Height – With Clearance to Open Dipper Door | 29.53 ft |

| Revolving Frame Tail Swing Radius | 30.51 ft |

| Cutting Radius – Maximum | 79.72 ft |

So, we have described the 14 largest excavators that are available in the world. But don’t forget that today there are different and even more powerful ones being made. As technology continues to improve, expect to see some absolutely enormous mechanical giants tearing up the earth in the next few years.