The 773 electric bobcat is a three-wheeled, all-electric mini-excavator. It is used for small excavating jobs or digging in compacted dirt. We will discuss the different problems that can arise and give tips on how to fix common issues with the 773.- Bobcat 773 electrical problems.

how to replace ignition switch on bobcat 773

1. Remove the seat.

2. Disconnect the battery cables.

3. Remove the wiring harness connectors from ignition switch.

4. Remove the nut and disconnect the rod from clutch/brake pedal.

5. Remove the two bolts and remove the ignition switch housing with key.

6. Rotate retainer clockwise and remove it from switch housing.

7. Remove the spring and push on retainer to remove lock cylinder from housing.

8. Insert tool into lock cylinder and push in on retaining pin to release lock cylinder from housing assembly

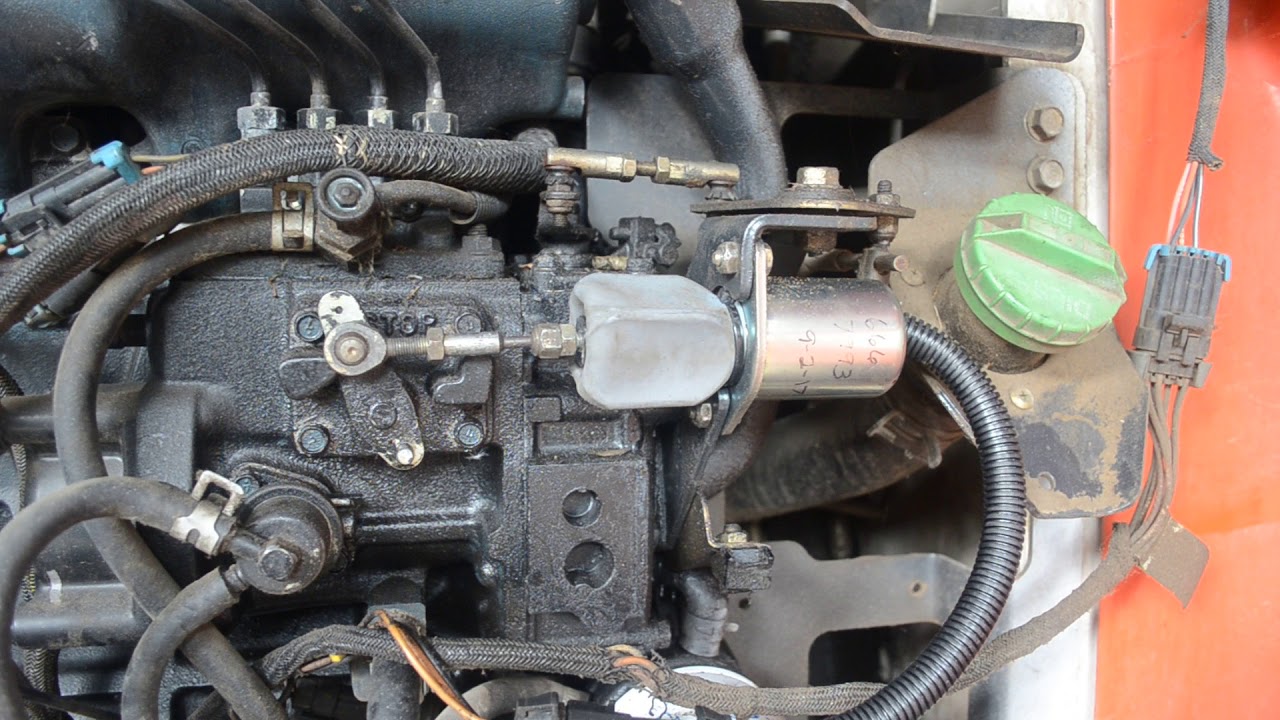

bobcat 773 electrical schematic

BOBCAT 773 SKID STEER LOADER Service Repair Manual S/N 517611001 & Above S/N 518011001 & Above S/N 518111001 & Above S/N 519011001 & Above

This is the Highly Detailed factory service repair manual for theBOBCAT 773 SKID STEER LOADER, this Service Manual has detailed illustrations as well as step by step instructions,It is 100 percents complete and intact. they are specifically written for the do-it-yourself-er as well as the experienced mechanic.BOBCAT 773 SKID STEER LOADER Service Repair Workshop Manual provides step-by-step instructions based on the complete dis-assembly of the machine. It is this level of detail, along with hundreds of photos and illustrations, that guide the reader through each service and repair procedure. Complete download comes in pdf format which can work under all PC based windows operating system and Mac also, All pages are printable. Using this repair manual is an inexpensive way to keep your vehicle working properly.

Service Repair Manual Covers:

Istruzioni di sicurezza

Comandi e strumenti

Istruzioni per l'uso

Manutenzione

Rimozione e installazione di componenti

Servizio motore

how to test a starter solenoid on a bobcat 773

1. Remove the starter solenoid from the Bobcat 773 by unthreading its mounting bolt. Pull out the starter solenoid from the battery box and set it aside.

2. Lay down the starter solenoid on a clean work surface and remove the two nuts that secure its wires to the terminals. Pull out the wires from their terminals and set them aside for now.

3. Inspect the wiring of the terminals for any signs of damage, such as rust or corrosion, which may cause a faulty connection between them. Replace them if necessary.

4. Reconnect the wires to their respective terminal posts and secure them with their corresponding nuts.

5. Reconnect the starter solenoid back to its mounting position on the Bobcat 773 by first threading in one bolt on its mounting flange, then threading in another bolt so that they cross each other, but do not tighten either bolts just yet.

6. Position a voltmeter on “DC” mode and make sure it is set to read at least 50 volts DC on its display screen.

7. Connect one end of a jumper wire to your voltmeter’s positive terminal clip and another end of that same jumper wire to one of your Bobcat 773 battery

these are the top four bobcat 773 electrical problems and solutions

the bobcat 773 skid steer loader is a 53-horsepower machine with a standard bucket capacity of 10.5 cubic feet. it has a maximum lift height of 11 feet, 4 inches, and a maximum load capacity at 50 percent of tipping load of 2,500 pounds.

when electrical issues arise, they’re often related to the starter, alternator or battery. since these components all work together, problems in one area often affect the others. if you have an electrical problem with your bobcat 773 skid steer loader, here are the top four things to check:

check for bad connections: if you have a bad connection in your battery or power system, this may be causing your starting issues or other electrical problems. clean any corrosion from the battery terminals and ensure all connections are secure. ensure that the alternator belt isn’t loose or worn out.

ensure the park brake is disengaged: if you have an issue disengaging the park brake, this can also cause electrical problems with the starter or other components. if you’re having trouble disengaging the park brake manually (or with the solenoid), ensure that there’s no debris blocking it from moving freely and get it repaired by a qualified mechanic as soon as possible.