What happens if you run a hydraulic pump backwards

Hydraulic pumps are used in a variety of settings, from agriculture to manufacturing. But what if you tried to use one backwards? You might be surprised at the results! In this article, we’ll explore the physics behind hydraulic pumps and see what happens when you run one backwards.

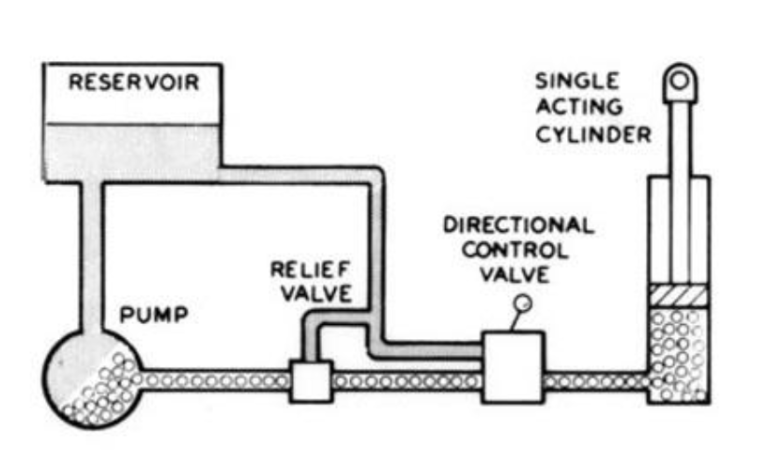

A hydraulic pump is a machine that uses pressurized fluid to move something. In typical use, the hydraulic pump sends pressurized fluid through a line to push or pull something else.

But what if you reversed the flow of the hydraulic fluid? In this situation, the pressurized fluid would go from the engine to the pump and back again. The main purpose of a hydraulic pump is to regulate pressure, so if you reversed the flow of the hydraulic fluid it would create a lot of pressure.

In fact, if you reversed the flow of hydraulic fluid for more than a few seconds, it could cause serious damage to both the pump and engine. So be careful when reversing a hydraulic pump!

What is a hydraulic pump?

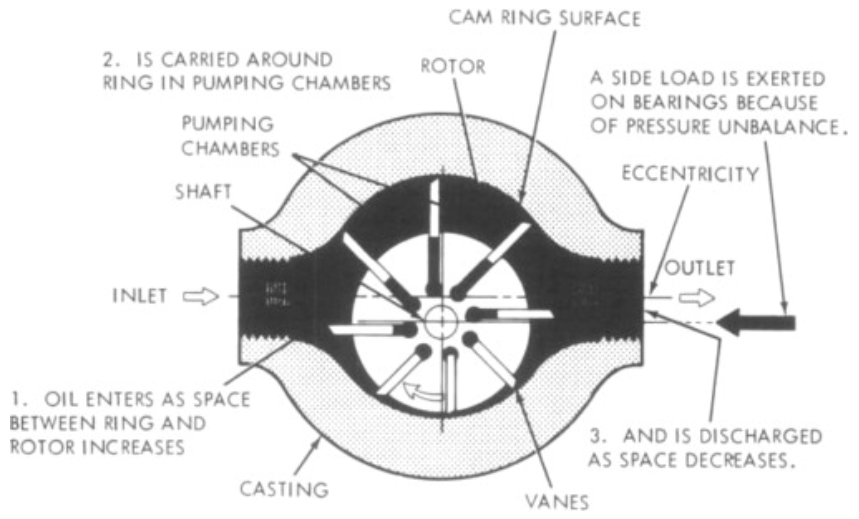

A hydraulic pump is a device used to move fluid by using the pressure of a fluid flow. They work by moving a pressurized fluid from one point to another through a pipe. When you run a hydraulic pump backwards, you create an imbalance in the fluid and can damage the pump or the system it’s running in.

Hydraulic pumps come in a variety of shapes and sizes, and can be used in a variety of applications. They’re used to move water, oil, gas, and other fluids around a plant or facility.

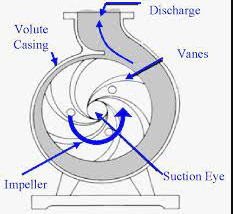

How does a hydraulic pump work?

A hydraulic pump works by using the force of a fluid to move an object or piston. When you run a hydraulic pump backwards, the fluid will try to push the piston in the opposite direction, but it won’t be able to because of the gearbox.

The gearbox allows the piston to move in a forward and reverse direction, which uses the power of the fluid to move the object or piston.

What are the dangers of running a hydraulic pump backwards?

If you attempt to run a hydraulic pump backwards, you will likely result in catastrophic damage to the machine and possible injury to yourself. A pump that is running in reverse is essentially trying to suck air out of a container instead of pushing hydraulic fluid in, and this can cause the piston to hit the bottom of the cylinder head with such force that it can shatter. In extreme cases, the suction can also detach the pump from the cylinder and cause it to rotate. If you have ever seen a hydraulic press come loose while it was in use, you have seen one example of what can happen when a hydraulic pump is run backward.

Why does running a hydraulic pump backwards cause problems?

When an engine is running, the pistons are moving up and down and the hydraulic fluid is being forced through the pump. When the engine is turned off, the pistons stop moving and the hydraulic fluid can no longer flow through the pump. This can cause problems because the pump may become blocked and unable to move fluid. The pressure from the fluid can also build up and cause damage to the engine or other components.

How to prevent a hydraulic pump from running backwards

hydraulic pumps are powerful machines, and if operated incorrectly can cause serious damage. Here are a few tips to prevent a hydraulic pump from running backwards:

1. Make sure the pressure relief valve is open before starting the pump. This will release any pressure that may be building up in the system.

2. Verify the correct fluid level in the reservoir before starting the pump. If the reservoir is low on fluid, the pump may not start.

3. Always use caution when operating a hydraulic pump, and consult with a qualified technician if you have any questions or concerns about its operation.

How does a hydraulic pump work? – When a hydraulic pump is running backwards, what happens?

A hydraulic pump is a machine that uses the pressure of pressurized fluid to move objects or fluids. When the pump is running in reverse, the fluid moves from the reservoir, through the pump, and back into the reservoir.

Drawings to help explain Conclusion: When a hydraulic pump runs backwards, the direction of the flow of fluid is reversed. This results in an opposite force on the device and causes it to stop quickly. 2

If you’ve ever worked on a hydraulic pump, you may have heard someone say to “never reverse the flow of the fluid.” This is because doing so can cause the device to stop quickly.

A hydraulic pump is a type of machine that uses fluid to move objects. When you reverse the flow of the fluid, you create an opposite force on the device. This causes the device to stop quickly and often damage it in the process.

The lesson here is simple: always be aware of the direction of the flow of fluid when working on hydraulic pumps. If something seems off, don’t do anything until you’ve checked with someone else or researched further. Doing so could prevent potential damage or injury.

Would you always know if your pump has been reversed?

If you have ever reversed a pump, then you know that it can cause damage. The most common damage is to the motor and gearbox. If the pump is reversed often enough, it can even cause the motor to overheat and fail.

When reversing a pump, it is important to be aware of any potential dangers. If you are not sure if your pump has been reversed, then it is best to take it to a mechanic or electrician for inspection.

Conclusion

If you’re like most people, you probably don’t worry too much about what happens if you run a hydraulic pump backwards. After all, it’s unlikely to happen and if it does, there’s bound to be some serious damage done. But in this article, we’re going to take a look at how running a hydraulic pump backwards can actually cause some pretty serious damage. So if you ever find yourself wondering what might happen if you did something stupid with your hydraulic equipment, read on!

What happens if you run a hydraulic pump backwards. please click topkitparts see more