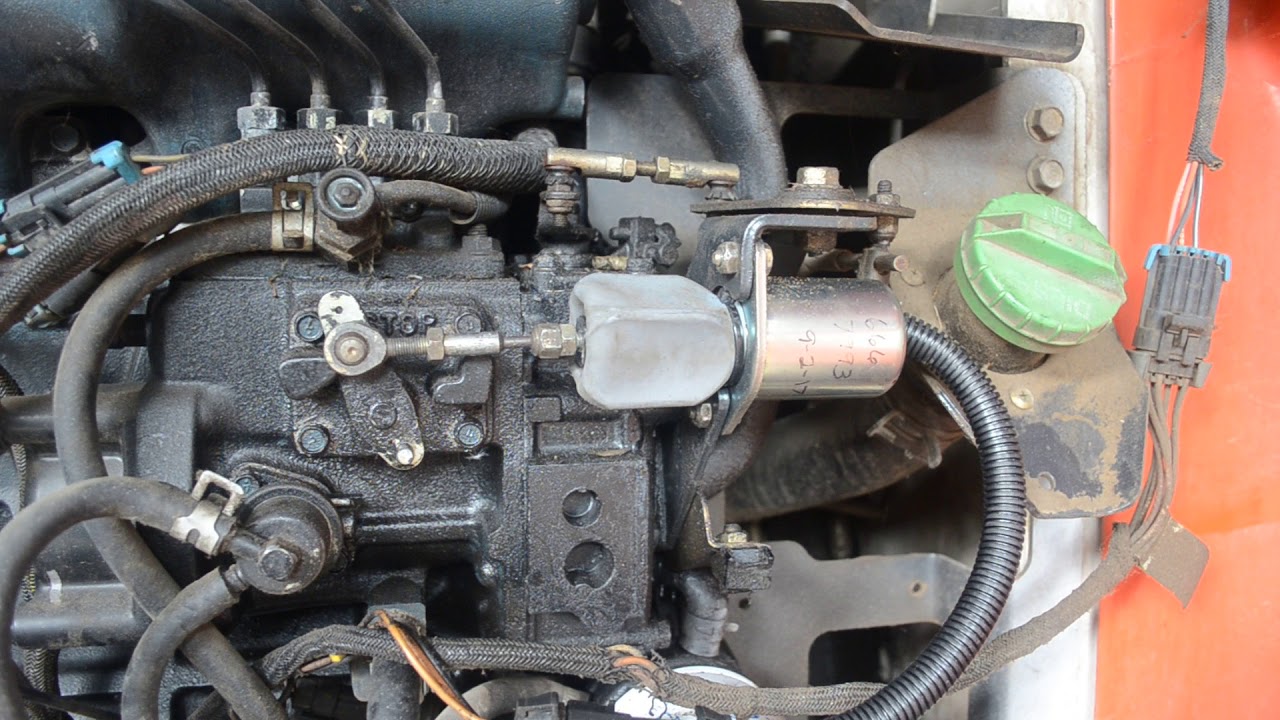

I am relating to you bobcat t770 engine problems and how to fix them. I can tell you it will be great for you. Because when I was searching for the same thing, I found a video on YouTube which give me an idea about the bobcat t770 engine problems and solutions.

Why does my Bobcat t770 engine smoke?

The first step to diagnosing an oil leak is to determine where the leak is coming from. The next step is to determine what color the oil is:

Black or gray smoke comes from the tailpipe. Black smoke indicates too much fuel and not enough air. Possible causes include problems with the fuel system, high idle, excessive load, and poor quality fuel.

Blue smoke indicates that engine oil is burning in the combustion chamber. This can be caused by worn valve guides or seals, excessive crankcase pressure or a defective PCV system.

White smoke indicates that fuel or water vapor is escaping into the exhaust system. Check for a cracked intake manifold gasket, damaged injector lines or faulty injectors.

How do I fix my Bobcat engine that has a loss of power?

If you have a loss of power when operating your Bobcat loader, it may be due to a clogged breather tube or a clogged hydraulic return filter.

The hydraulic return filter is a simple solution that can be found under the floorboard. It’s an easy fix if you have the right tools. If this doesn’t solve the problem, then it is probably due to a bad breather tube. The breather tube is located on top of the engine compartment and can be easily removed by loosening the clamps with a pair of pliers. Once you have it off, you will notice oil drippings. This is normal and not a cause for concern. Before putting the tube back in place, clean off any dirt and debris with a rag or paper towel to ensure proper ventilation of the engine compartment.

If you still experience power loss after switching out filters and cleaning your breather tube, then contact your local dealer for further assistance.

How do you stop your T770 from overheating?

The printer is not defective, the fuser has a fault. The fuser is the part that heats up as paper goes through it, to help dry the ink. It’s also the part that makes your printed pages hot when they come out of the printer.

The fuser has a built-in sensor to detect when there is an abnormally long time between a page being sent and fed into the machine. This would be an indication of a paper jam or a sheet of paper being caught in the feed path somewhere. In such situations, the fuser must be switched off to avoid damaging it with too much heat. You can see this effect if you send something to print, and it starts coming out slowly because there’s a tiny little corner of paper stuck somewhere and every time it feeds a new sheet into the machine, it finds this little bit of paper and stops for about 15 seconds before trying again. Your prints will be very hot by the time they finally emerge from your printer

To fix this issue:

1. Turn off your printer

2. Unplug it from the power source

3. Open its lid and check for any jammed papers inside

4. Remove them if found any

5. Close its lid properly

6. Plug back in

What causes the loss of acceleration in my T770?

If the loss of acceleration occurs every time you start your truck, there is likely an issue with your fuel system. When there is a problem with the fuel system, it can cause the truck to misfire and lose power.

If the loss of acceleration occurs intermittently and not every time you start your truck, it may be caused by an issue with the transmission or engine. The internal components of both systems can become worn over time.

Checking for codes can help determine which system is failing or malfunctioning before any parts are replaced.

How do I fix the clogged fuel filter?

The fuel filter is located underneath the driver’s side door. There is a small plastic cover that you can pry off to get access to the filter. It’s not in a bad location, but it can be difficult to remove the clamps on both ends of the filter due to the small area you are working in.

A few tips:

Remove the vent hose from the top of the fuel tank first. This makes more room to work in and it also prevents gas fumes from accumulating while you’re working on it.

Use a pair of vise grips to clamp down on the filter clamp tabs before you try to loosen them. This prevents them from spinning when you try to remove them.

The factory tool for removing these clamps is basically just a pair of long needle-nose pliers with special gripping jaws. I used an old pair of snap ring pliers from an auto parts store (similar to this) and they worked great. They have longer handles than regular needle nose pliers which gives you more leverage for opening up and closing down the clamps.